YJNPACK Honeycomb Paper Core Sleeve Making Machine

آلة تصنيع أكمام ورق قرص العسل هي عبارة عن معدات خاصة لصنع أكمام أو أكمام ورق قرص العسل. أكمام ورق قرص العسل هذه مصنوعة من ورق قرص العسل المتشابك بإحكام، وهي أيضًا مادة خفيفة الوزن ومتينة وصديقة للبيئة، فضلاً عن كونها بديلاً صديقًا للبيئة وفعالًا من حيث التكلفة لتبطين الغلاف البلاستيكي.

غلاف مبطن من ورق قرص العسل. تم تصميمه خصيصًا لمختلف المنتجات والحاويات الهشة، ويُستخدم في تغليف النقل الوقائي أو حماية التخزين، مثل زجاجات النبيذ والزجاجات والعلب والسيراميك والأواني الزجاجية وما إلى ذلك.

من السهل استخدامه وسهل التركيب، فقط ضع زجاجة النبيذ فيه، مما يوفر حماية فعالة ومصنوع بالكامل من ورق الكرافت. كما أنه يعد بديلاً صديقًا للبيئة لأكياس الفقاعات البلاستيكية، مما يحمي الأشياء الثمينة الهشة أثناء النقل—طريقة صديقة للبيئة لتجنب الضرر.

حول مبدأ عمل آلة تصنيع غلاف ورق قرص العسل

مبدأ عمل آلة تصنيع غلاف ورق قرص العسل هو استقبال لفافة ورق وتحويلها إلى غلاف ورق قرص العسل عبر سلسلة من العمليات. سيتم ذلك بالخطوات التالية:🌱📦

*تغذية الورق: تستقبل الماكينة لفة الورق وتدخلها في عملية التصنيع.

*الترابط: يتم وضع مادة لاصقة أو غراء خاصة على الورق لربط الطبقات معًا.

*التموج: يتم تمرير الورق عبر سلسلة من بكرات التموج، وذلك بالضغط على الورق في سلسلة من البكرات المتناوبة بشكل وثيق

أنماط بنية قرص العسل.

*القطع والتشكيل: قم بقص وتشكيل ورق العسل إلى حجم الغلاف أو الغطاء المطلوب.

*التجفيف: اترك المادة اللاصقة أو الغراء لتجف للتأكد من أن غلاف ورق قرص العسل يحتفظ بشكله وسلامته البنيوية.

*الإخراج: جمع أو تكديس أكمام ورق العسل الجاهزة للتعبئة والتوزيع.

🌏الميزات:

*التنوع: يمكن إنتاج أحجام وتكوينات مختلفة من أكمام ورق قرص العسل لتناسب متطلبات المنتج المختلفة.

*الكفاءة: تعمل الماكينة بسرعة ويمكنها تحقيق إنتاج واسع النطاق.

*صديقة للبيئة: أكمام ورق قرص العسل مصنوعة من مواد معاد تدويرها، مما يجعلها بديلاً صديقًا للبيئة

إلى حلول التعبئة والتغليف التقليدية.

*خفيف الوزن وعالي القوة: يتمتع ورق قرص العسل بنسبة قوة إلى وزن ممتازة، مما يقلل من الوزن الإجمالي مع توفير الحماية.

تعتبر آلات تصنيع الأكمام الورقية على شكل قرص العسل مناسبة للصناعات مثل التعبئة والتغليف والأثاث والبناء والسيارات وغيرها من الصناعات التي تتطلب حلول تغليف واقية وصديقة للبيئة.

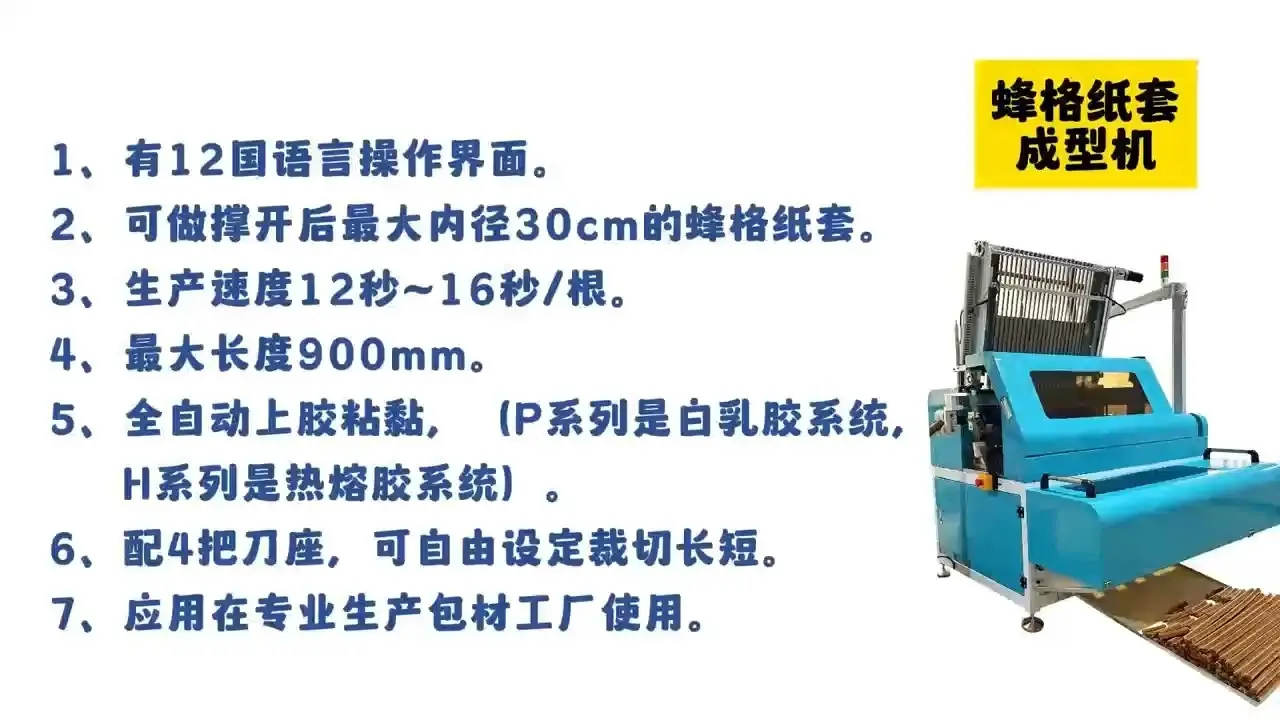

معلمات آلة تصنيع غلاف ورق قرص العسل

| غرض | آلة صنع غلاف ورقي على شكل قرص العسل |

| ضمان | سنة واحدة |

| حجم الماكينة | 3200*1380*1380 مم |

| وزن | 800KG |

| قوة | 3KW |

| مصدر الهواء | 0.6 ميجا باسكال |

| تقرير اختبار الآلات | متاح |

| سرعة تشكيل المادة اللاصقة المنصهرة الساخنة | حوالي 9 ثواني/قطعة |

| سرعة تشكيل الغراء الأبيض | حوالي 15 ثانية/قطعة |

| المواد التكيفية | لب ورق كرافت على شكل قرص العسل. الارتفاع: ١٠-١٥ مم، العرض: ٨-١٦ مم، الطول: ٢٠٠-٦٠٠ مم، سمك الورق: ٥٠-٨٠ جم. |

الدعم الفني والخدمة

*إرشادات التثبيت: توفير مواد فيديو التثبيت والإرشادات عبر الإنترنت من مهندسي البحث والتطوير

* خدمة ما بعد البيع: خدمة ما بعد البيع 3 إلى 1، استجابة فورية

* مزايا المصنع: تسليم الجملة المصنع مباشرة، سعر الجملة المصنع الفريد

* تخصيص فريد من نوعه: لدينا مهندسي البحث والتطوير الخاصين بنا، وقبول الشعار المخصص ولون العلامة التجارية

* ضمان لمدة عام: استبدال مجاني لقطع الغيار الشائعة خلال فترة الضمان. في حال تعذر حل المشكلة عبر الإنترنت، سنرتب لمساعدتنا في الموقع.