YJNPACK Honeycomb Paper Core Sleeve Making Machine

A honeycomb paper core sleeve making machine is a special equipment for making honeycomb paper sleeves or sleeves. Made of tightly interlaced honeycomb paper, these honeycomb paper sleeves are also a lightweight, durable, and environmentally friendly material, as well as an environmentally friendly and cost-effective alternative to plastic wrap cushioning.

Honeycomb paper padded sleeve. It is specially designed for various fragile products and containers, used for protective transport packaging or storage protection, such as wine bottles, bottles, cans, ceramics, glassware, etc.

It is easy to use and easy to put, just put the wine bottle in it, which can effectively provide cushioning protection and is completely made of kraft paper. It is also an environmentally friendly alternative to plastic bubble bags, protecting your fragile valuables during transportation—an eco-friendly way to avoid damage.

About The Honeycomb Paper Core Sleeve Making Machine Working Principle

The working principle of the honeycomb paper core sleeve making machine is to receive a paper roll and convert it into a honeycomb paper sleeve through a series of processes. Will go through the following steps:🌱📦

*Paper Feed: The machine receives the paper roll and feeds it into the manufacturing process.

*Bonding: A special adhesive or glue is applied to the paper to bond the layers together.

*Corrugation: The paper is passed through a series of corrugation rollers, by pressing the paper into a series of closely alternating

patterns of honeycomb structure.

*Cutting and Forming: Cut and form the honeycomb paper to the desired sleeve or lid size.

*Drying: Allow the adhesive or glue to dry to ensure the honeycomb paper sleeve retains its shape and structural integrity.

*Output: Collect or stack finished honeycomb paper sleeves for packaging and distribution.

🌏Features:

*Versatility: Various sizes and configurations of honeycomb paper sleeves can be produced to suit different product requirements.

*Efficiency: The machine runs fast and can realize large-scale production.

*Eco-friendly: Honeycomb paper sleeves are made from recycled materials, making them an environmentally friendly alternative

to traditional packaging solutions.

*Lightweight, High Strength: Honeycomb paper has an excellent strength-to-weight ratio, minimizing overall weight while providing protection.

Honeycomb paper sleeve making machines are suitable for industries such as packaging, furniture, construction, automotive, and other industries that require protective and environmentally friendly packaging solutions.

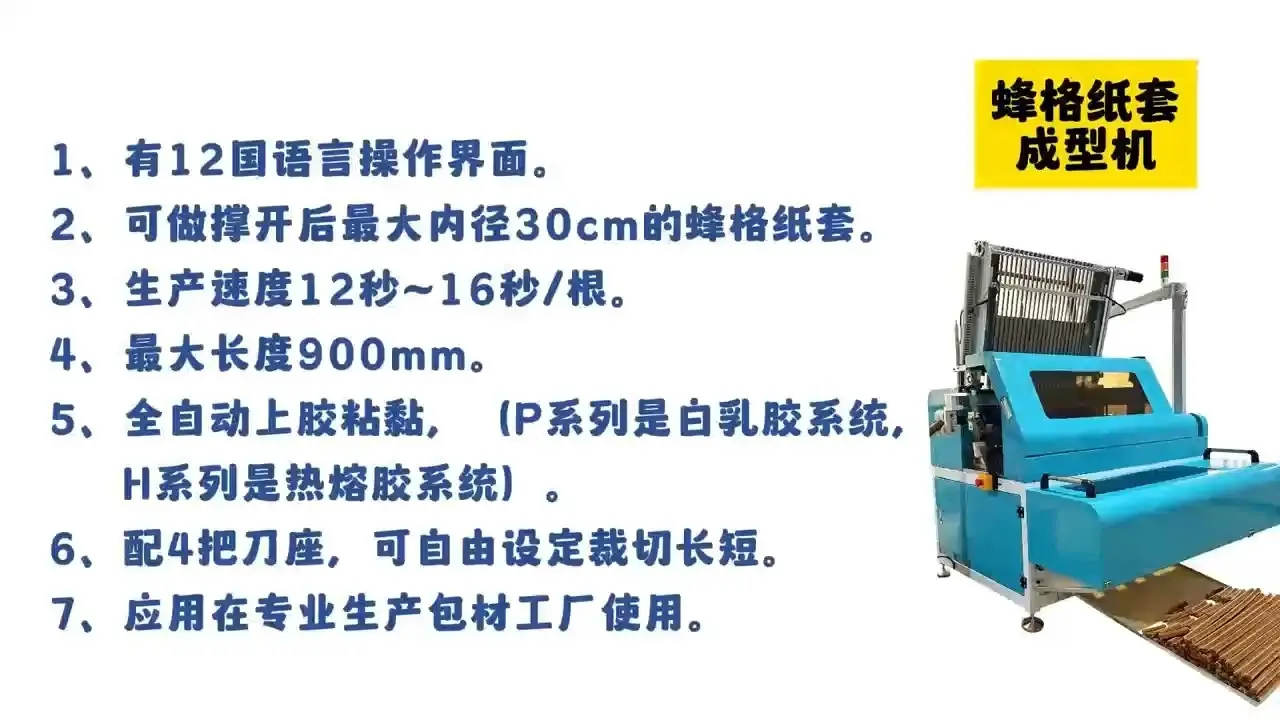

Honeycomb Paper Core Sleeve Making Machine Parameters

| Item | Honeycomb Paper Core Sleeve Making Machine |

| Warranty | 1 year |

| Machine Size | 3200*1380*1380mm |

| Weight | 800KG |

| Power | 3KW |

| Air Source | 0.6mpa |

| Machinery Test Report | Provided |

| Hot Melt Adhesive Forming Speed | About 9 seconds/piece |

| White Glue Forming Speed | About 15 seconds/piece |

| Adaptive Material | honeycomb kraft paper core. Height 10~15mm, width 8~16mm, length 200~600mm, paper thickness 50g~80g |

Technical support and service

*Installation guidance: Provide installation video materials and online guidance from R&D engineers

* After-sales service: 3-to-1 after-sales service docking, immediate response

* Factory advantages: Direct factory wholesale delivery, unique factory wholesale price

* Unique customization: Have our own R&D engineers, accept customized logo and brand color

* 1-year warranty: Free replacement of common spare parts during the warranty period. If the problem cannot be guided online, we will arrange for a dedicated person to provide on-site guidance