YJNPACK Kraft Paper Cushion Void Fill Machine NP-EC760

The paper cushion machine from YJN offers a variety of systems that transform paper rolls into packaging material for any application from speedy lightweight filler to strong cushioning pads. The paper cushion machine works by compressing the kraft paper into a crimped shape, resulting in an efficient cushioning effect, which is proven to prevent damage to the goods during transportation and provides a positive environmental protection unpacking experience for the end-user. This innovative packaging technology is designed for heavy, dense, or high-value products that are often difficult to transport. Industries requiring increased levels of protection include industrial manufacturing, home improvement, medical devices, and automotive.

The kraft paper cushioning system provides protective blocks and supports and provides a variety of paper cushion machines to choose from, which can be wound or coiled, effectively packaging and protecting light, heavy and sharp products.

Advantage:

1. Solid cushion paper pad has high stiffness and strong supporting performance.

2. Effectively buffer, fill and fix the products.

3. The paper pad equipment has a fast paper discharging speed, of up to 30 meters per minute.

4, kraft paper into pad rate as high as 92%, high material utilization rate.

Paper Cushion Machine Product Description:

1. Industrial use with subsidizing, weighing only 78kg.

2. With adjustable paper length and multiple modes.

3. Easy to install, and flexible enough to integrate into most pack stations.

4. One-year quality guarantee with professional technical guidance.

YJPACK best quality Model NP-EC760 Paper Void Fill Cushion Machine Factor

Paper Void Fill Machine NP-EC760 Features

The paper cushion machine NP-EC760 has a patented gear system, which can extrude more three-dimensional paper pads

and provide stable cushioning. Humanized and safe paper outlet design, and the setting of power off when the cover

is opened are integrated to prevent employees from being injured. The overall design is dominated by three-dimensional,

which makes your packaging process more simplified.

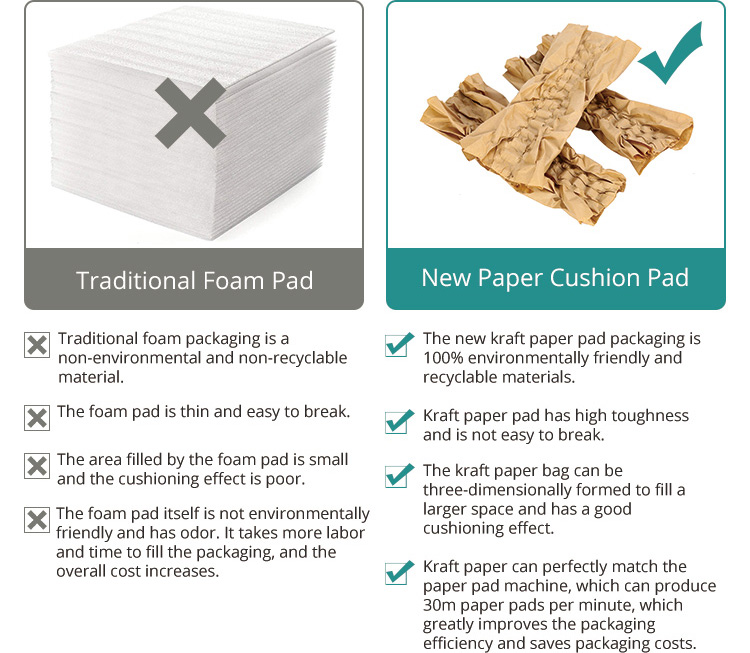

*Alternatives to traditional foam

*30CM/S efficient output,3 modes to switch freely

*Customize colors and logos to enhance the corporate image

*A variety of operating modes to meet a variety of packaging needs

*Foot pedal setting, convenient and quick

*Easy operation with LED control panel

*Carton void filling, 100% recyclable packaging

*Angle and height adjustable

*Can be used with recycled paper

*Strong protective performance, can accommodate most items

Product Paramateres

| Item: | Kraft Paper Void Fill Cushioning Machine NP-EC760 |

| Modes: | Auto Mode, Single Mode |

| External hardware: | foot switch, USB2.0 data cable (connect to PC) |

| Speed: | 30CM/S |

| Power: | 400W |

| Voltage: | 100-240V AC 50/60HZ |

| Weight: | 120kg |

| Size: | 85*70*170cm |

| Packaging Size: | 92cm*75cm*170cm |

Kraft Paper Cushion Machine Custom Logo

We provide professional designers to design brand logos for products and customize exclusive brand colors and outer

packaging, and create your own brand products.

If you are looking for a reliable and professional protective packaging manufacturer, we will be one of your best choices.

Paper Cushion Machine Factory Photo

The Paper Void Filling Solution can create custom-length paper pads that automatically cut to the corresponding

set length through the internal constantly rotating gear, motor, and cutter section, making it an ideal paper system

for cushioning, blocking, and support. Adopt dual-factory production mode and international operation center to

ensure the normal operation of product delivery and a series of jobs.

Paper Cushion Machine Original Statement

The paper cushion machine NP-EC760 is exclusively developed and designed by YJNPACK. There have been a lot of

imitations on the market, please look for the original factory.

Kraft Paper Cushion Machine Details

1.New Paper Cushion And Multifunctional Control Area

Safe the unique compression technique means added volume - Paper void filling system cushions boast up to 30% more cushioning volume and higher compressive strength than other paper systems.

2.LCD Panel Display And Adjustable Head Angle

Easy Reliable easy-to-operate equipment with efficiencies like programmable keypads and hands-free foot pedal control.

3.Easy To Use And Recycled Kraft Paper

Versatile Multiple machine configurations, flexible features, and add-on components allow you to fit the equipment to your packaging process and engineer the most efficient production methods for your packing requirements.

Comparison of Kraft Paper and Traditional Packaging

Using traditional plastic, and bubble wrap:

1. Traditional plastic and foam packaging are not environmentally friendly and difficult to recycle

2. Bubble packaging is easy to cause garbage and messy placement

3. Cause extra manpower and time to pack

4. Cause unnecessary environmental problems and increase packaging costs

Packaging with Kraft paper pad material:

1. Kraft paper pad packaging is 100% recyclable and environmentally friendly material

2. Kraft paper is not easy to tear and provides buffer protection for the package

3. Kraft paper can effectively fill the gaps in the carton to prevent items from being damaged during transportation

4. Kraft paper pad packaging does not occupy space and provides packaging efficiency, saving packaging costs

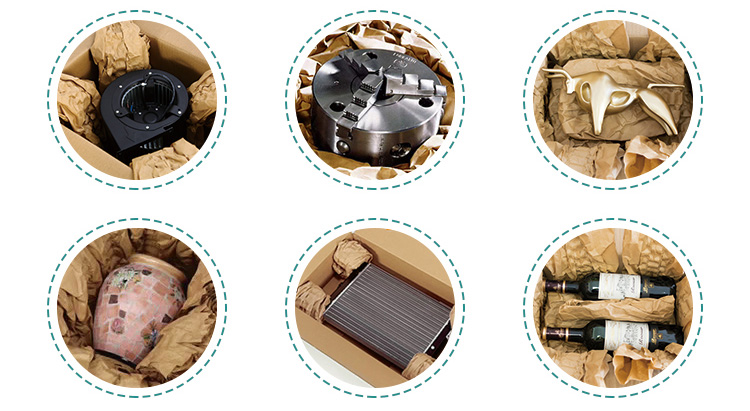

Kraft Paper Packaging Display

After the paper cushion machine compresses and folds the kraft paper pad, it forms a filling and protective effect on

the article. If you need to transport large items, electronics, valuables, heavy items, sharp-shaped items, fragile items, etc.,

then the kraft paper pad packaging is definitely one of your best choices.

The kraft paper cushioning system provides protective blocks and supports and provides a variety of paper cushion machines

to choose from, which can be wound or coiled, effectively packaging and protecting light, heavy and sharp products.

About YJNPACK

YJNPACK makes packaging simpler and more eco-friendly. We are a professional buffer packaging manufacturer,

providing you with a one-stop solution.

YJNPACK continues to drive the development of industrial packaging through innovation, launching more than 5

new products every year, productivity, and a trusted product brand. We are committed to researching and developing

a range of new environmentally friendly packaging alternatives to reduce packaging waste and plastic content. This

means more savings in transportation costs and less pollution.

Direct factory price, 1 piece delivery, and 1-year warranty, are our promises.

FAQ

1. What is the MOQ?

We accept sample orders and trial orders. Normally, our MOQ is 1 Pc.

2. Are you a manufacturer and trading company?

We are an eco-friendly packaging manufacturer with 16 years of experience.

3. What are your warranty terms?

We provide a 1 year warranty for our cushion packaging machines.

With the increasing demand for online-specific packaging in the market, there are more and more ways to replace

plastic packaging materials. Plastic pads have been replaced with recycled and recyclable paper pads to reduce

single-use plastic. This also means that sustainable packaging will eventually replace plastic packaging, which will

be suitable for any product sold through e-commerce, namely kraft paper pads, specially designed to prevent

The product moves within the packaging to prevent damage.

With this automated paper void filling system, you can ensure high throughput and safe and environmentally friendly

packaging paper materials. After start-up, the machine can produce paper pads directly at the packaging station in just

a few seconds, with the fastest speed. Speed to produce efficient fillings.

Thanks to the sturdy kraft paper pad, the paper pad protection system can withstand medium to large packages

between 5 and 50 kg - the perfect solution for transporting spare parts, electronic components, ceramics, and more.

In addition to the paper pad machine NP-EC, we have other compact and economical paper pad systems that, like all

filling systems, can also be integrated into existing distribution lines.

If you want to try to dig out more kraft paper packaging, then the paper bubble machine is a good choice, a packaging machine

that can produce paper bubble film with concave and convex bubbles on the surface.

Next is the question you want to know.

-

1. What Is The Paper Cushion Machine?

-

2. What Is The Paper Cushion Machine Used For?

-

3. The Benefits Of Sustainable Kraft Paper Filling

-

4. What Is Kraft Paper Filling?

-

5. Is Kraft Paper Recyclable?

-

6. Why Is Everyone Using Paper Cushion Filling Systems?

-

7. What Is Kraft Paper Made Of?

What Is The Paper Cushion Machine?

The paper cushion machine is an economical and practical packaging machine. The kraft paper is compressed

and folded through a series of technologies so that the paper becomes a paper pad with the functions of filling,

wrapping, filling, and supporting, preventing the damage of items caused by collision and extrusion during transportation.

It is also one of the sustainable solutions to replace traditional plastic packaging and is suitable for various large

enterprises, e-commerce enterprises, home furnishing, and other industries.

Kraft paper packaging material is the cheapest and easiest packaging solution, it comes in a roll or a stack, which

saves most of the storage space, and you can dispose of it your way when you receive it. Kraft paper can accommodate

most products, and the paper cushion machine also provides printing brands and logos.

Paper cushioning machine NP-EC has different operation modes, you can set different lengths according to your

own needs and the setting of pulleys can be moved according to different places to meet more flexible packaging needs.

The paper cushion machine is a multi-functional system packaging. The setting of the foot pedal also frees the

hands and can meet the packaging needs of most items, such as fragile items, valuables, handicrafts, glass products, etc.

It is a carton gap-filling one of the best options for a solution.

What Is The Paper Cushion Machine Used For?

The kraft paper void fill machine can be used with recyclable paper, and kraft paper and is ideal for gap filling of cartons.

It is very suitable for small and medium-sized enterprises, e-commerce enterprises, households, warehousing, and logistics,

and other industries and protective pads for some transport items so that your items can be transported safely.

And this paper cushioning wrap can replace the traditional foam plastic packaging, which can improve the neatness of

the packaging and will not cause excess storage waste, save manpower, and improve packaging efficiency.

Kraft paper cushioning systems are the ideal protective packaging solution for heavy-duty products. With single or double-layer

kraft paper pads, even heavy products can be safely blocked and supported in the carton with cushioning on all sides. And with

a flexible touch screen, at the touch of a button, the paper pad machine NP-EC will automatically produce and cut strong, flexible,

and highly malleable paper cushions. For the material of kraft paper, customers can choose from different paper types according

to their needs. FSC® certified materials are also available.

The Benefits Of Sustainable Kraft Paper Filling

Paper void filling system is the most valuable commodity in the packaging industry. No need to determine the size of the

carton to use and ensure the product is safe and safe to transport to its destination. Paper cushioning allows

you to safely transport delicate and fragile goods.

Traditional plastic foam filling is not only bad for the environment, but it is also difficult to recycle.

The paper cushion machine is used together with renewable kraft paper, which has strong toughness. It is a multifunctional

packaging machine, which adopts an LED screen combined with pedal mode operation, which saves most of the time while

packaging.

What Is Kraft Paper Filling?

Using kraft paper to compress and fold it can form a buffer protection effect, which is an effective way to

fill the empty space in the box and prevent the product from moving around during transportation, which

can improve the safe transportation rate of the product and reduce the cost of a lot of transportation.

Kraft paper is characterized by its superior strength compared to other paper alternatives. Pulp does not require

extensive bleaching, which not only protects the environment but also does not destroy the integrity of the paper

itself. And kraft paper is 100% fully recyclable when wet. Used together with the filling system paper pad machine,

it can improve the packaging efficiency, and customize the printing logo service, which can enhance the reputation

of the company and create more benefits for you.

Is kraft Paper Recyclable?

Kraft paper uses reduced lignin and a high sulfur ratio, the chemical process behind making kraft paper is also more

sustainable and 100% recyclable. And kraft paper has a strong protective performance, and will not cause excess storage

waste like plastic foam. It is not only environmentally friendly but also has cushioning and protective properties after

compression and folding. The preferred alternative to plastic bubble wrap.

Why Is Everyone Using Paper Cushion Filling Systems?

The kraft paper void fill machine is an economical and simple-to-use packaging machine and an effective solution for carton gap

filling. And it is very suitable for logistics, warehouses, assembly lines, offices, e-commerce, express outlets, physical stores,

and other occasions. It can be used for space-filling and packaging medical supplies, fragile products, daily necessities,

digital electronics, food, luggage, and other products to protect goods from damage and reduce costs and damage rates.

The paper cushion machine allows you to customize the logo or brand message according to your exact requirements; from

the details of each one to the quantity you need at one time.

The paper cushion machine void-fill sustainable packaging solution is fast, easy to use, and most importantly, environmentally friendly.

What Is Kraft Paper Made Of?

Kraft paper was originally manufactured by Carl F. Dahl in the 1880s. Kraft comes from German and means strong. It is a very strong and

tough paper and is often used to make kraft shopping bags, cardboard, paper pads, and honeycomb paper. Due to the multi-faceted nature

of the kraft paper, also prevents the bag from slipping off the pallet.