Understanding The Impact Of Damage Costs On E-commerce Packaging On Sustainability

How To Reduce Damage Losses While Ensuring Profits?

During the busy packaging season or holiday promotions, it is particularly important to choose the right packaging method. Companies

will conduct a series of quality control checks before shipping goods to reduce damage costs. But the "hidden loss costs" cannot be ignored.

At NRTEC, and from my own experience, can all of these be prevented? This involves the entire packaging process from product packaging to delivery.

To solve the problem from the root, we believe that any hidden costs and damage rates that can be prevented should not be considered acceptable,

but should be avoided and prevented.

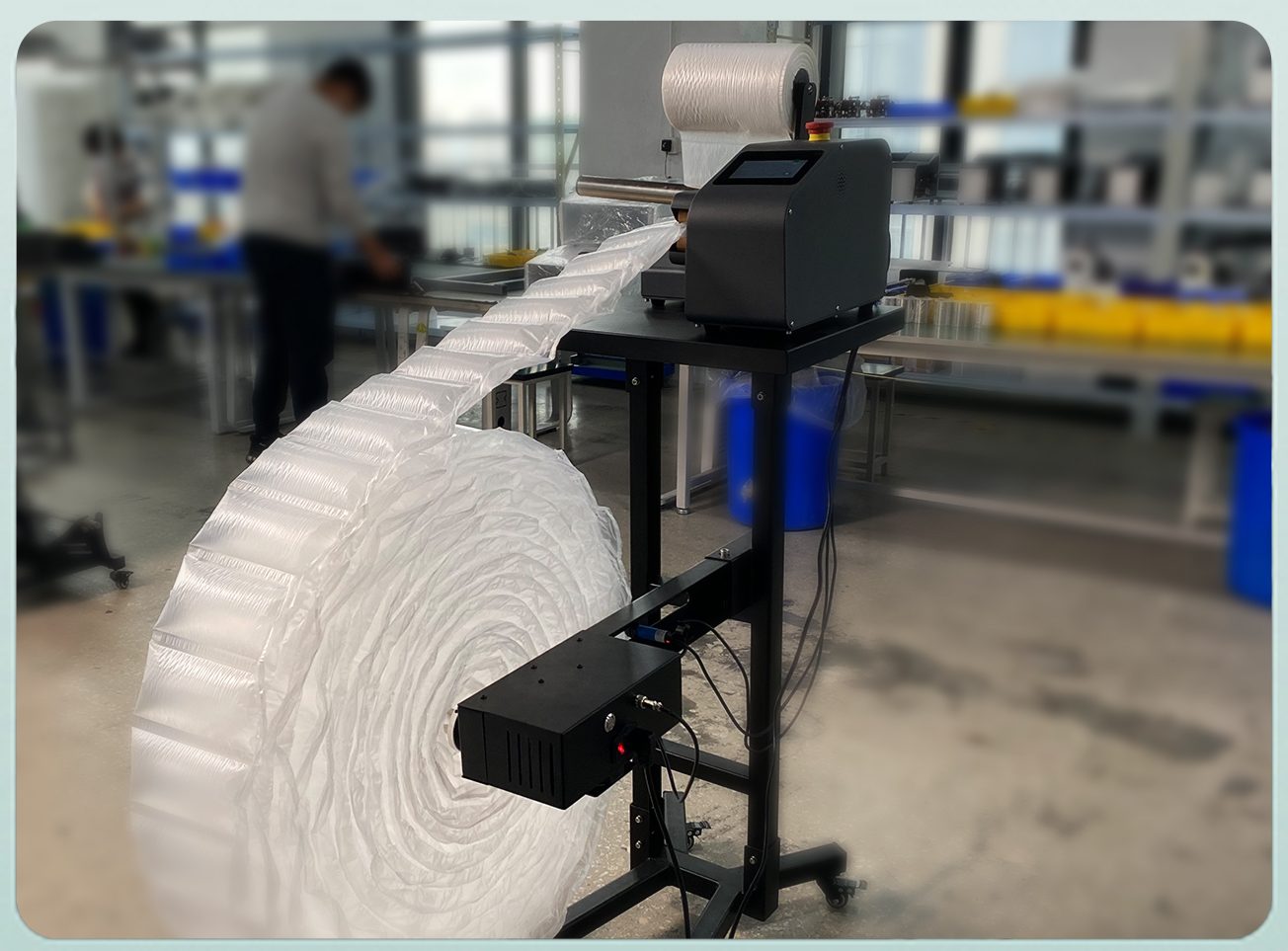

While trying to solve the problem of preventing cargo damage, we use air cushion film to wrap items and fill the boxes, which shows that the number

of damaged products has decreased and the safe delivery rate has gradually increased.

Most retailers ignore sustainable benefits when considering safe delivery. For example, some plastic bubble films are still in use in the market, and they

rarely replace them with films that can be thrown directly into recycling bins. Although the purpose of safe delivery is achieved, the environmental impact

of packaging processing after transportation is 5%, or even more immeasurable.

According to my experience above, from the perspective of retailers, it is particularly important to choose the right packaging materials and

innovative packaging solutions to achieve efficient packaging reduce the impact on the environment and meet the conditions of

sustainable development, and it can also ensure the dual benefits of safe delivery of goods.

Let Consumers And Retailers Profit At The Same Time

Air cushion film is one of the protective packaging materials that can replace traditional plastic bubble packaging. It can be used on demand and

can be 100% recycled. The 99.5% air content inside it can effectively play a shock-absorbing and protective role, and can also meet sustainable development

while fulfilling safe delivery.

The real sustainable impact is not whether it is made of recyclable materials or whether it can be recycled at the roadside, but whether it can eliminate the risk of

damage and eliminate the risk of the item doubling, tripling, or even quadrupling its environmental footprint.

The air cushion film can be used in conjunction with the air cushion machine to produce the required length of air cushion film on demand for filling and

packaging in the box, which increases the overall packaging speed by 20%. After receiving it, customers can safely put it into the recyclable box without affecting the

environment.

China holds large-scale online promotions every year: Double Eleven and Double Twelve. If large brands have gradually switched to

sustainable packaging materials such as air cushion film packaging and paper air pillows, they can customize logos, colors, and sizes. Such

brand-colored packaging not only retains old customers but also attracts new customers, making the company's development a big step forward.

NRTEC, as a logistics protection packaging manufacturer and service provider, helps brand companies and retailers provide special protection packaging solutions

to ensure that items can be delivered safely, use the least amount of materials to minimize waste generated by procurement and production, and achieve true

sustainable development.