Desktop Paper Cushion Machine PPO-1 Protective Packaging Manufacture

The paper cushion machine is also known as the kraft paper void filling machine. Its working principle is probably that the flat kraft paper is rolled and extruded into a kraft paper pad with a patterned buffer through the internal gears. The original design of the paper outlet of the paper cushion machine is to take the 45° angle as the best paper outlet angle. From the perspective of mechanics and ergonomics, 45° is the most comfortable angle for work in any field.

About Paper Cushion Machine PPO-1

This desktop paper cushion machine replaces the traditional standing and movable paper cushion machines, it can

be placed in any office area for packaging, its size is 63*40*37cm, and it will not take up too much office area even if

It can also be used in household packaging.

The paper void filling machine can also be equipped with a shelf to become a movable paper cushion machine, a

simple multi-functional operation interface, and different paper pad lengths can be set according to requirements.

Accept different modes of operation, single mode or automatic mode, etc., and produce air cushions at a speed of

12m/min to improve the packaging speed. Compared with traditional packaging, paper cushion packaging is more

environmentally friendly and cost-effective. Safe and high-grade packaging material with support, protection,

and filling.

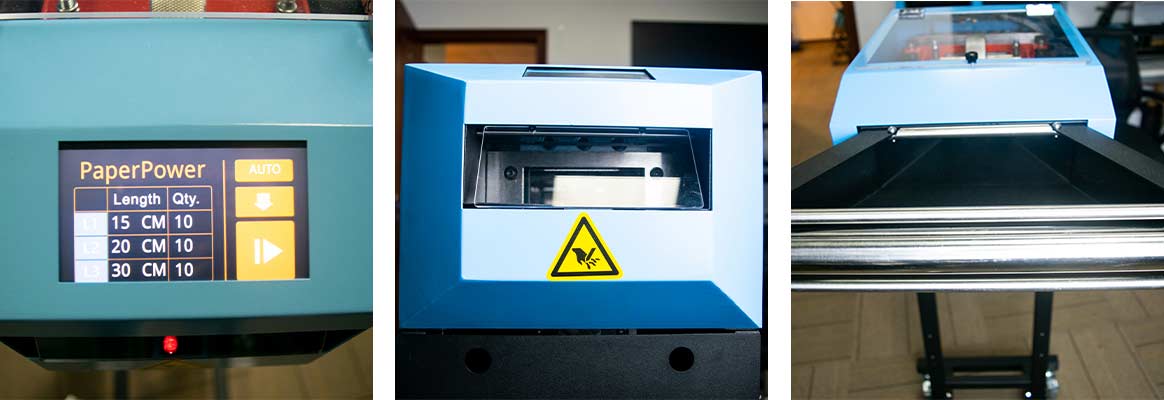

Paper Cushion Machine PPO-1 Details

Multifunctional Operation

The paper pad machine PPO-1 has a simple and basic touch key area, which gets rid of the complicated operation

process. The 45° angle of the paper outlet can meet the packaging operation of people of various heights.

Compact Molding Effect

The gear structure inside the paper pad machine is a high-grade raw material that has been screened out. It can

accurately roll and fold the kraft paper, and the better the molding, the better the protection.

Paper Cushion Machine Structural Details

Switch Area Emergency Stop Switch Paper Pad Forming Gear

LED Screen Paper Outlet Paper Tension

Bubble Wrap vs Kraft Paper Pad

About YJNPACK

YJNPACK makes packaging simpler and more eco-friendly. We are a professional buffer packaging manufacturer,

providing you with a one-stop solution.

YJNPACK continues to drive the development of industrial packaging through innovation, launching more than 5

new products every year, productivity, and a trusted product brand. We are committed to researching and developing

a range of new environmentally friendly packaging alternatives to reduce packaging waste and plastic content. This

means more savings in transportation costs and less pollution.

Direct factory price, 1 piece delivery, 2-years warranty, are our promises.

Next is the question you want to know.

1. What is Kraft Void Filler?

2. What Is Kraft Void Fill Used For?

3. Is kraft Void Fill Recyclable?

What is Kraft Void Filler?

Kraft filling paper is a packaging filling material based on natural raw materials. It is mainly used for filling the blanks

inside the carton and protecting the transportation items. When you need to pack various large items, fragile items,

or valuables, Kraft paper pads are the first choice for supporting and filling protective packaging materials in cartons.

From this method, it can be concluded that even if the transportation logistics is more than 7 days, the damage rate

of the items can be greatly reduced.

What Is Kraft Void Fill Used For?

As the name suggests, the void filler is used as a protective material for the packaging in the carton, supporting, filling,

not only that but also improving the neatness and image of the packaging appearance. Not only suitable for packing

heavy items but also for packing some valuable cosmetics, storage protection, fragile items, etc.

Is kraft Void Fill Recyclable?

Using natural kraft paper as raw material, without adding any harmful substances, 0 plastic packaging materials, so you

can dispose of it according to your own ideas, it is a reusable and roadside recyclable paper packaging solution.

YJNPACK, make your packaging simpler and make your packaging more eco-friendly.

We provide you with a one-stop service, allowing you to shop with peace of mind.

*OEM&ODM service

*Self-owned factory guarantees the delivery time

*The whole machine is guaranteed for two years

*During the warranty period, free replacement parts

*Troubleshooting problems, professional and technical personnel answer one-on-one

*Provide solutions and troubleshooting videos

*Provide professional service instructions

*24 Hours Online Reply