YJNPACK Air Cushion Machine 2.0 AP400

The air cushion machine, also known as the air pillow machine, is the best solution for protective packaging. Its working principle is to form an air pillow or pillow by filling the air cushion film with air, thereby forming a high-efficiency cushioning effect. The air cushion machine is suitable for air cushion films of different sizes and accepts packaging customization.

It can be used as needed, saving materials and meeting most transportation requirements. The air pillow machine can produce 100% recycled air cushions made of 100% recycled materials.

This kind of air cushion packaging with a transparent color appearance is very suitable for companies that value high-quality protective performance packaging, which not only improves the company's brand awareness and impression but also ensures product safety and sustainability.

Air Cushion Machine Description:

1. No need to warm up (Add heating wire structure)

2. Lower prices, higher revenue than the previous generation

3. Adjustable speed from 65 feet to 89 feet per minute to meet different speed demands.

4. Ideal for large-scale warehouses.

5. Works with all types of film, and suits all your packing needs.

6. Speed, air, and temperature adjustable.

7. Able to work with overhead hopper, winder, or basket.

Air Cushion Machine AP400 Features

The newly upgraded 2.0 air cushion machine adds a heating wire structure on the original basis. The optimization of the

internal structural parts includes the replacement of the material of the outer shell. The gray matte texture material is used,

which can reduce the material cost and increase the aesthetics of the product. Moreover, it can be connected with smart

devices, which can be said to meet the needs of a large part of industrial-grade packaging.

The 2.0 air pillow machine can automatically set various parameters such as air, temperature, and length, and the structure

of the newly upgraded machine is also designed with fewer "wear parts" to provide long-term reliability and reduce aftermarket

replacements. It produces air cushions and air pillows that can be used as void fillers, block/support, and top/bottom pads to

protect cargo. Its compact size makes it ideal for decentralized packaging operations.

Ideal for socially distant, decentralized e-commerce packaging operations, the 2.0 Air Cushion Packaging System is operated with

an Air Cushion System Delivery System Rack, and its ergonomic working height helps support employee health. Equipped with a

blow-up rack unit is part of the Air Cushion Packaging System's robust range of inflatable protective packaging solutions.

-Fast speed, average 15m/min, improve your packaging efficiency

-It can be used as needed and can be stacked on the shelf in rolls when not in use, without taking up space

-Transparent color appearance, enhance the image of corporate packaging

-Use the air cushion system on demand to save most of the storage space

-Ease of use for high packaging productivity and low maintenance

-Easily adjustable to control air volume, speed, temperature, and length

-Compact design, all-in-one air packing machine, easy to operate and maintain

-Air Bubble Film Machine, which can inflate air cushions of different sizes to meet your different needs

-Widely used in e-commerce businesses, logistics companies, and factories, where goods need to be protected from

damage during transportation

-Sufficient stock, fast delivery of samples in 3-5 days

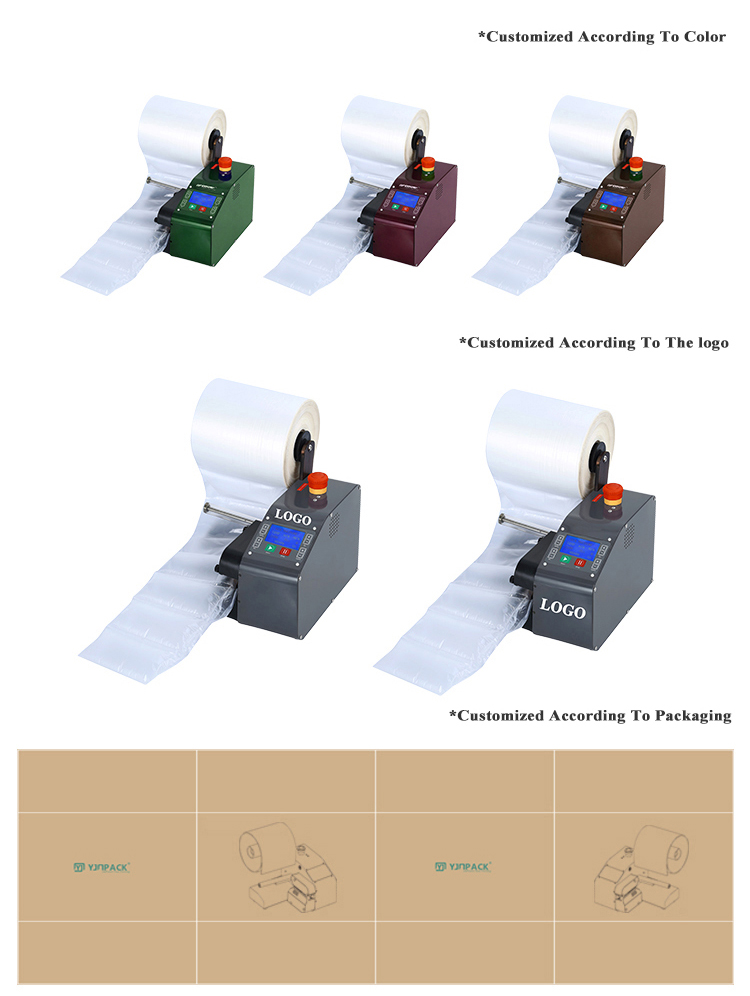

Air Bubble Machine Custom Logo

We provide professional designers to design brand logos for products and customize exclusive brand colors and outer

packaging, and create your own brand products.

If you are looking for a reliable and professional protective packaging manufacturer, we will be one of your best choices.

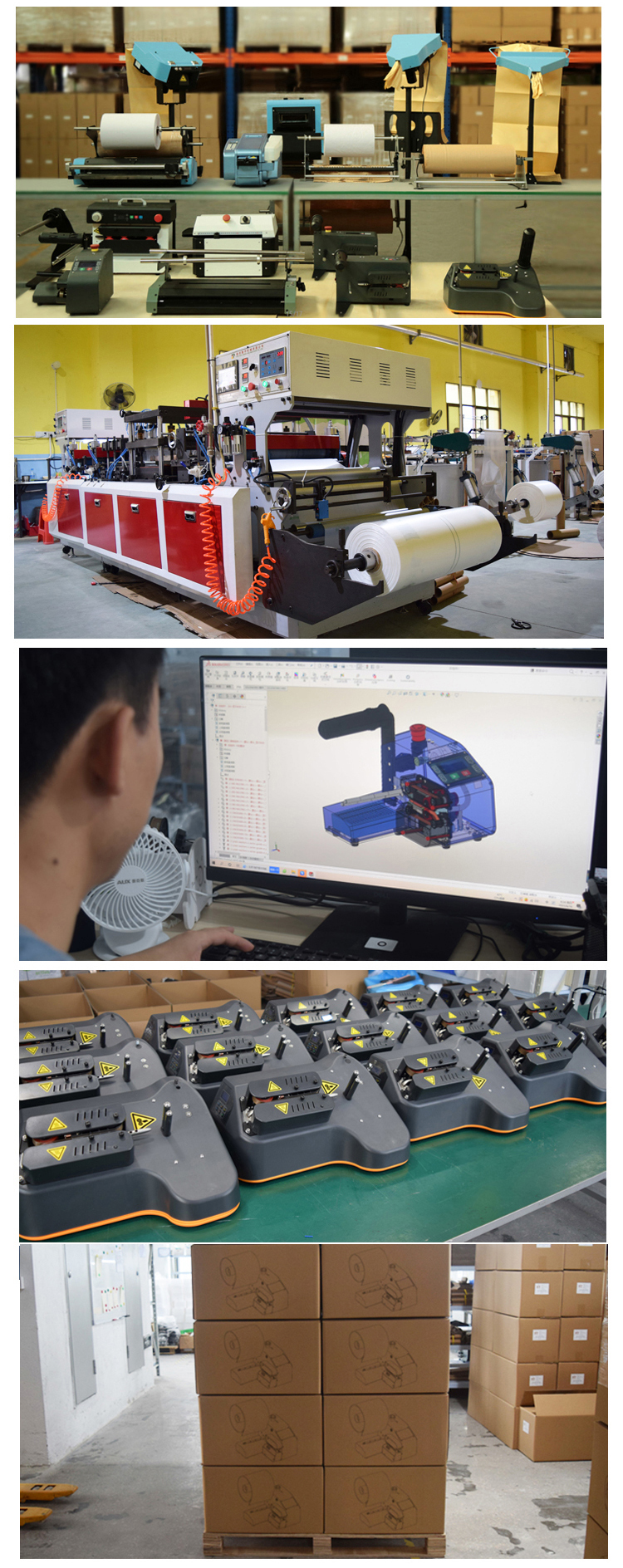

Air Bubble Machine Factory Photo

2.0 Air packing Machine AP400 can be added to any production line and can be used in connection with a collection frame,

blow-up rack, foot pedal, and other equipment to directly increase the packaging efficiency to 30%. The frosted texture of

the appearance makes your packaging more textured and advanced. From the selection of raw materials to the determination

of use, it controls the quality while controlling the cost.

Feather-weight and reliable shock-resistant, air cushion films are the best protective packaging for sensitive products.

Equipped with Air Cushion 2.0 or other equipment, it can be integrated into existing packaging processes - including in

combination with automatic packaging lines and storage containers at the packaging station.

Air Cushion Packing Machine CE And PSE certificate

The air cushion packing machine AP400 is exclusively developed and designed by YJNPACK. The patent number

is ZL 2019 3 0142873. There has been a lot of imitations on the market, please look for the original factory.

Air Cushion Packing Machine Details Images

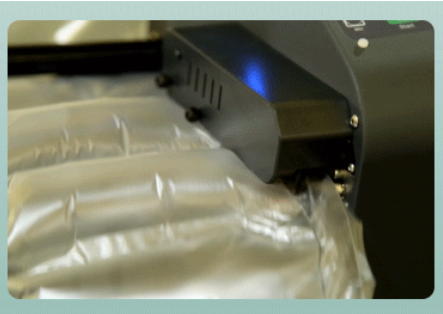

High Speed

Use an air cushion filling machine for packaging, the speed is 15m/min, stable performance, and the air pressure

of each air column is uniform. Inflatable packaging at start-up.

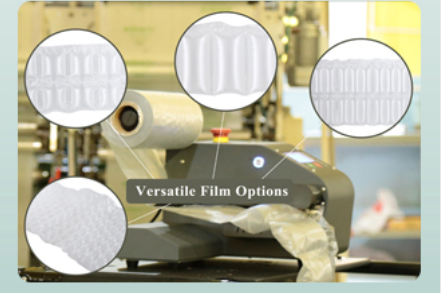

Versatile Film Options

The air cushion filling machine AP400 can produce various specifications of air pillows, air bubbles,s, and air tubes

on-demand to meet various packaging needs.

Smart And Simple

Featuring a user-friendly LED touch screen, you can adjust air, temperature, length, speed, and more.

Quick change of belt and blade, Save space. The small machine takes less warehouse room. Installation is fast,

and the warranty time is 1 year, providing quality assurance.

External Function

The movable Basket System, foot pedal, Winder System, and Overhead Hopper Film Delivery System can be

connected externally. Make your packaging more flexible.

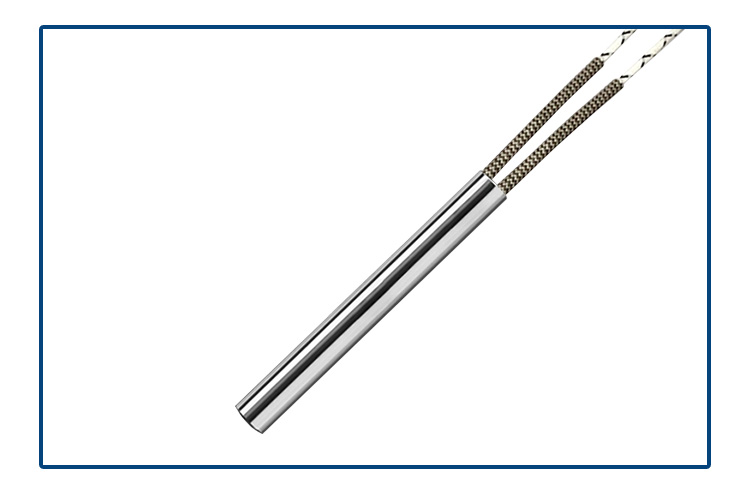

Temperature Control System

Imported heating system accessories, the air rate inside the air cushion film is sufficient to ensure the safety

of the transported items and prevent the transported items from being damaged due to collision and extrusion.

Air Bag Machine Production Process

All air packaging machines are put into production after the 3D design of appearance, shape, and structure by

our R&D engineers. Each process after production is inspected by professionals to ensure that each air cushion

packaging machine is the best.

About YJNPACK

We are a professional manufacturer of buffer packaging machines, providing a variety of packaging machine materials

and products, escorting thousands of express terminals, and obtaining maximum benefits for your market. We will be

your most reliable packaging solutions manufacturer partner.

*Has an R&D center, production center, global sales network, and after-sales service

*Committed to the global marketing of various protective packaging equipment and materials

*Obtained multiple professional certificate licenses

*Strict quality inspection department and sales, delivery, and brand system

*Excellent service, high-quality products, and competitive prices

*Provide a full range of packaging solutions for your maximum benefit

FAQ

1. What is the MOQ?

We accept sample orders and trial orders. Normally, our MOQ is 1 Pc.

2. Are you a manufacturer and trading company?

We are an eco-friendly packaging manufacturer with 16 years of experience.

3. What are your warranty terms?

We provide a 1-year warranty for our cushion packaging machines.

When you select the air cushion film of the corresponding size and load it into the air bubble machine AP400,

the internal intelligent operation will automatically identify and automatically match the optimal system settings.

This automatic loading and running efficiency make machine operation simple, eliminating the need to set up

and adjust other operations and eliminating human operator error.

When the air packing machine is energized and inflated, it will produce a series of automatic operations, which

can automatically inflate and produce a strong, consistent seal. Compared with other packaging materials, the

air bubble machine makes everything simple and efficient.

As the e-commerce channel has experienced unprecedented growth relative to the past, and everyone is more

concerned about the damage rate that has a catastrophic impact on profits, 'YJNPACK''s air pillow machine

AP400 can meet the increasing demand and improve efficiency, while air cushion film Provides the most effective

solution to protect high-value, fragile items, minimize damage costs, and enhance customer experience. "

Moreover, all air packaging machines can produce various pillow shapes directly on demand at the packaging station,

which can be air-cushion film, bubble film, etc., thus saving valuable storage space. The 2.0 air pillow machine can

directly produce various air cushions, the air pillows are very flexible and can be used to cushion, block, support, or

wrap sensitive products.

Next is the question you want to know.

1. What Is The Difference Between The 2.0 Air Packaging Machine AP400?

-

2. What Is Air Pillow Machine AP400?

-

3. What Is The Air Cushion Machine Used for?

-

4. Why Is The Air Bubble Film A Protective Pad?

-

5. How Long Can The Air Pillow Film Stay Inflated?

-

6. Why Use An Air Bubble Machine Or Air Cushion For Transport Protection?

-

7. How Does An Air Cushion Work?

-

8. What Is The Importance Of Air Cushions?

What Is The Difference Between The 2.0 Air Packaging Machine AP400?

-

1. In use, the 2.0 new air bag machine has changed the original structure and added a heating wire module,

-

so the 2.0 air cushion packaging machine can be used immediately without heating and energizing.

2. In terms of appearance, the outer shell of the 2.0 air cushion film machine is made of pattern texture material, which

makes it look more upscale and can be customized in color, logo, and outer packaging.

3. In terms of price, the 2.0 air pillow packaging machine is more economical and affordable than the original one, which can

save costs and double the profit.

What Is Air Pillow Machine AP400?

As the name suggests, the air cushion packing machine is to fill the air cushion or air pillow with air to form a filling material

to protect the transported items. Replace traditional foam and plastic packaging.

Air Packaging Machine AP400, weight only 6kg, speed 15m/min, small and easy-to-use air cushion film machine, used

to produce air cushions and air pillows and can be used on-demand, does not take up storage space, is a cost-effective

solution for packaging and transportation. When you want to use it, you can directly tear it by hand without using

other tools, simplifying a lot of packaging steps, which will save your warehouse costs and transportation costs,

and improve your packaging efficiency. Air cushion film machines are used to pack fragile goods.

1. High speed.

2. Perfect Sealing.

3. No air leakage.

4. Convenient maintenance.

5. Precision machining.

6. Temperature control system.

What Is The Air Cushion Machine Used for?

The air cushion packing machine is formed by inflating the air cushion film to form an air cushion or an air pillow, which

can form different types of air cushions to protect the product from damage caused by collision and extrusion

during transportation and provide excellent gap-filling, wrapping, and cushioning protection. Will reduce your

material cost, warehouse cost, labor cost, and shipping cost.

Why Is The Air Bubble Film A Protective Pad?

The reason is that the air cushion has very good shock resistance. On impact, the pad absorbs shock across its

the entire surface and provides more protection than traditional packaging, springing back to securely hold your product.

How Long Can The Air Pillow Film Stay Inflated?

It will not stay inflated for more than 24 hours. If you have an air cushion packing machine, it is easy to inflate. It can be

inflated during use, saving material. Once inflated, it releases a little air within 24 hours.

Why Use An Air Bubble Machine Or Air Cushion For Transport Protection?

Like other packaging, its purpose is to protect the goods in transit so that they arrive at their destination perfectly

and safely. The air cushion can be used on-demand, saving space and cost, and is the best choice for protecting

transport items.

1. Significant protective effect: the air cushion has excellent shock resistance, which can reduce the damage to items

during transportation

2. The packaging efficiency is amazing: the speed of the machine is 15m/min, and there are cracks between

the air cushion films, which can be directly torn by hand, without other tools, improving work efficiency.

3. On-demand use means that it will not occupy storage space and save materials.

4. The transparent air cushion film can also print logos and brand information to enhance corporate reputation.

5. They are a cleaner way to pack because no dust is created.

How Does An Air Cushion Film Work?

An air cushion film is a kind of air cushion pillow filled with gas. It is divided into air cushion and air bubble. After inflation, they will

generate air resistance, and the contact area with the surface is very small. Therefore, the friction force can be made smaller

on a certain basis.

What Is The Importance Of Air Cushions?

Air cushions are just another way for air and airflow to exist. A flat air cushion is filled with air to form an air cushion pillow. The

high-quality cushioning and shock absorption properties greatly reduce friction, so that the transported items can be delivered

safely in a good transport environment.

| Item | Inflatable Air Cushion Machine |

| Model | 2.0 AP400 |

| Warranty | 1 Year |

| Logo & Color | Accept logo and color customization |

| Certificate | CE, PSE, FSC |

| Port Of Departure | Xiamen Port |

| Applications | Busy warehouses, E-commerce, Stores, Express logistics, etc |

| Application | 200mm,20µm,700M;400mm,20µm,450M;600mm,20µm,250M |

| Parameters |

Power: 150W |