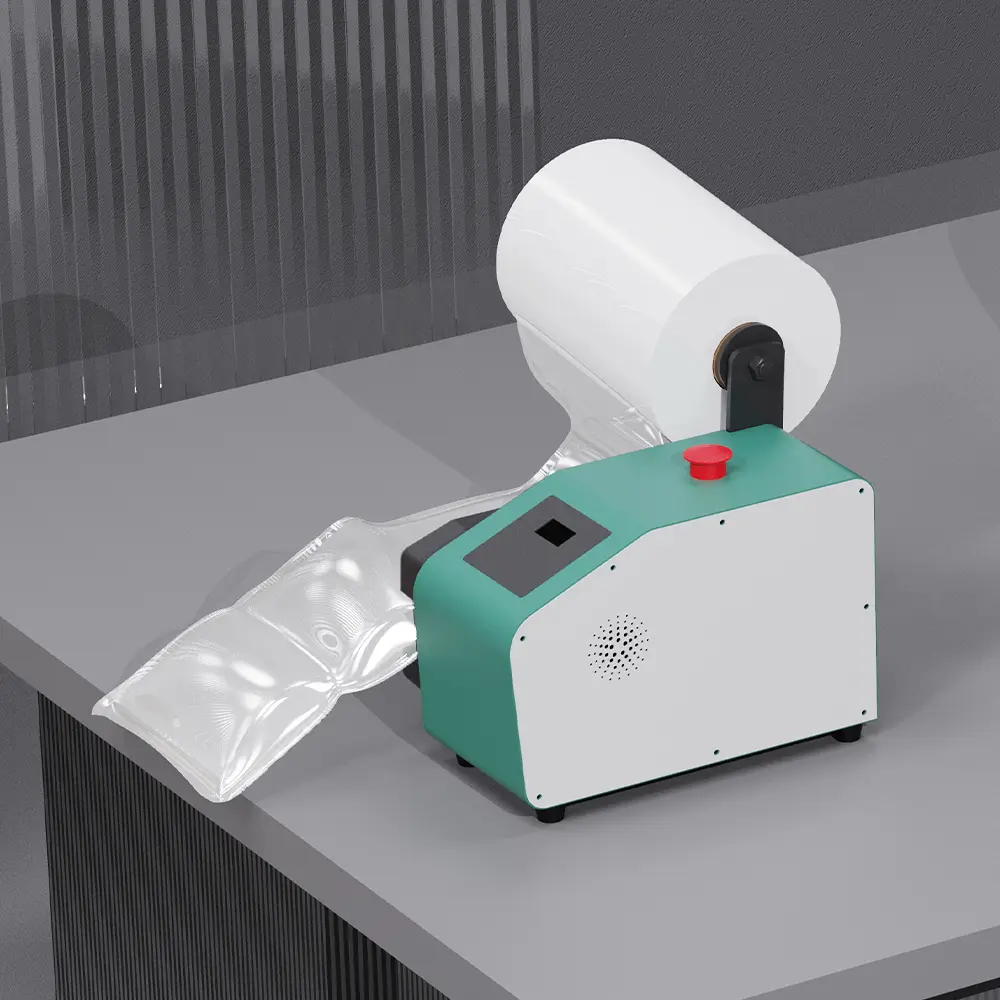

Beltless Air Cushion Machine 16m/min High Speed Production Inflatable Packaging Equipment

At the same time, it supports the production of various cushioning materials such as bubble film, air cushion film and air pillow film, which is suitable for the transportation packaging needs of electronic products, furniture, medical equipment and other industries, helping small and medium-sized factories and distributors to achieve efficient and stable packaging output at a lower cost.

Industry pain points and solutions

Pain points: high equipment maintenance costs, insufficient production flexibility, limited budgets, and cost-effective solutions

Beltless air cushion machine LA300 solution:

*Beltless transmission system: eliminates the risk of belt breakage and reduces annual maintenance costs by 65%

*15-second heating wheel quick-release technology: no tools required for manual replacement, reducing downtime by 90%

*Button programming control: setting air volume/temperature/meters only requires 3 steps, no complex training required

*Entry-level price + industrial-grade performance: single machine is compatible with 5 types of membrane materials, with an average daily production capacity of 8,000 meters

Air cushion Machine Inflatable packaging equipment Detailes

Diversified Packaging Options

Applicable to various specifications of air cushion films/air pillow films, etc., to meet the packaging needs of different occasions.

Revolutionary beltless design

Adopting gear direct drive system, the beltless structure can avoid frequent belt replacement, reduce the replacement frequency of wearing parts, and avoid frequent downtime caused by traditional belt wear.

Extreme maintenance experience

The modular design of the heating wheel can be replaced in just 2 steps, saving time for replacing accessories, open frame structure, and cleaning and maintenance efficiency increased by 70%

Key setting system

Physical button + LED digital display screen combination, anti-mistouch and adapt to dust environment, simple and easy to use, reducing employee training time.

Diversified customization

We are the source manufacturer with our own R&D department, providing body color and brand color customization and function customization.

Product Parameters

| Operation mode | Physical keys |

| Speed | 16m/min((0-100 adjustable) |

| Power | 300W |

| Voltage | 220V |

| Air volume | 0-100 adjustable |

| Temperature | 0-250℃ adjustable |

| Weight | 9.85kg |

| Size | 336mm*350mm*325mm(D*W*H) |

| Packaging Size | 410mm*350mm*310mm(D*W*H) |

All-aluminum smart control core power is equipped with industrial-grade brushless motor movement, which can run for 80,000 hours without wear and tear, and intelligent electronic commutation to achieve efficient production.

Deep adaptation of application scenarios

*Cross-border logistics providers: quickly produce air cushion films of different thicknesses to match 3C products/fragile products with graded protection

*Furniture manufacturers: wrap table corners/glass with wide bubble films to reduce the transportation scratch rate by more than 90%

*Regional distributors: customize LOGO bubble bags for customers to expand the profits of packaging value-added services

*Auto parts packaging: produce thickened shockproof bubble bags, wrap precision sensors/headlight components, and pass ISTA-3A transportation tests

*Cosmetics industry: customize pink/green brand-color antibacterial air cushion films to match the high-end shape of beauty products, or produce small-sized bubble bags to perfectly match lipsticks, perfume bottles and other special-shaped products

*Heavy machinery exports: quickly switch to 800mm wide bubble pillow films to wrap the edges of metal accessories to prevent rust and scratches

*Green packaging solutions: compatible with degradable PLA film materials, help brands meet the requirements of the EU SUP plastic ban, produce recyclable bubble bags, and reduce customers' comprehensive packaging costs