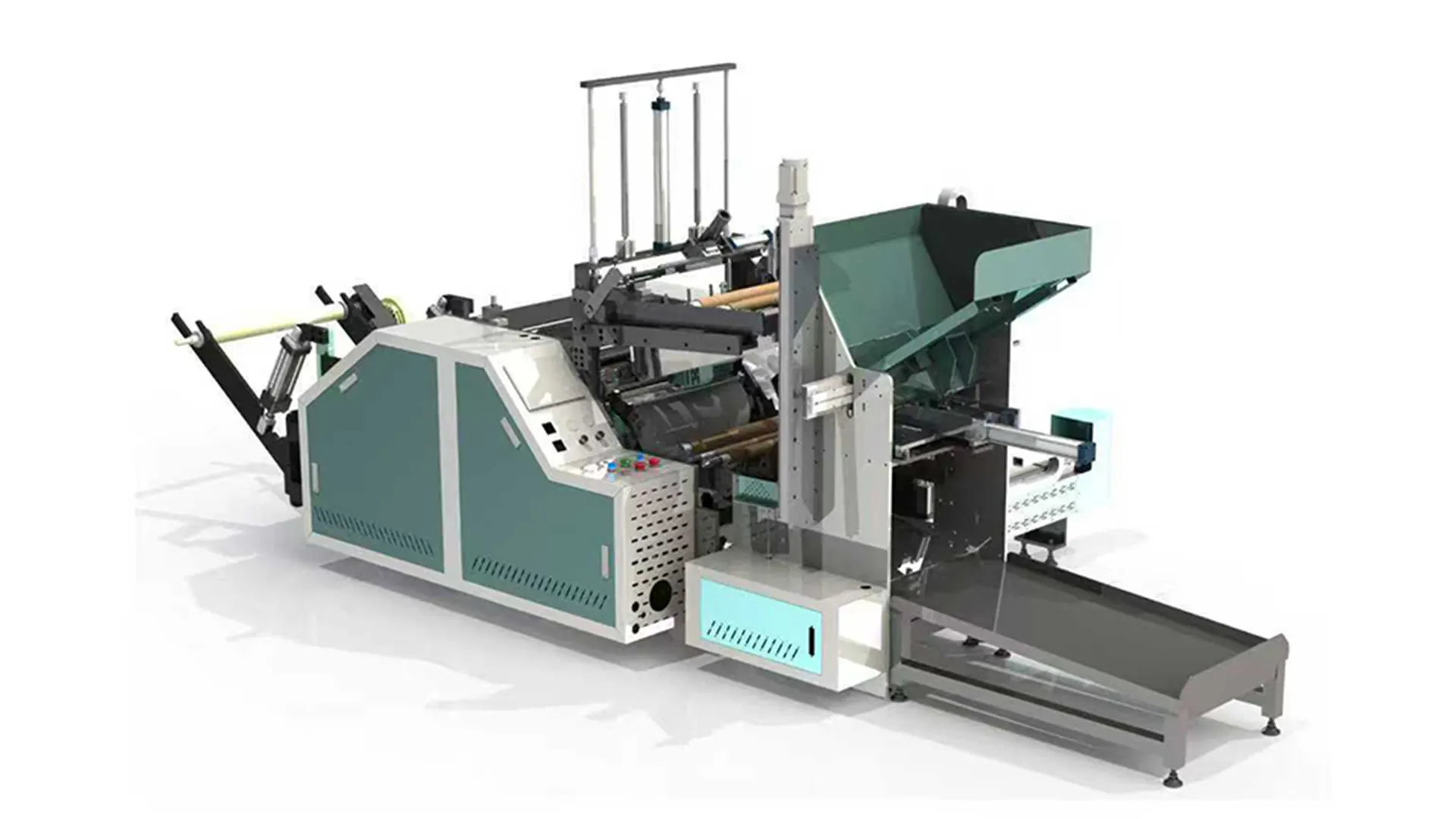

Yjnpackフルオートマチックハニカムペーパー製造機

全自動ハニカム製紙機の動作原理について

全自動ハニカム製紙機の生産ラインは、高度な機械設計と制御システムを採用し、自動供給、成形、プレス、切断といった主要工程を含む生産プロセスの自動化を実現しています。また、自動チューブローディング装置と自動補正システムを備え、効率的で信頼性の高い生産を実現します。

高速成形・プレス技術を基盤とし、110個の同期電動シリンダー修正装置を備えています。一連の切断・成形工程と300ロールの摩擦巻き取り工程を経て、クラフト紙を迅速に成形・プレスし、ハニカム構造を形成し、最終的に様々な仕様のハニカム紙を生産します。

全自動ハニカム紙ロール製造機生産ラインは、ハニカム紙ロールを製造するための効率的で自動化された生産システムです。

ハニカム製紙機:動作原理と製造プロセス

1. 原材料の準備:

• クラフト紙ロールの製造:生産ラインでは高品質のクラフト紙を原料として使用します。表面紙は通常、より丈夫で外層に使用され、芯紙は内側のハニカム構造に使用されます。

2. 紙加工:

• 裁断: 正確性と一貫性を確保するために、紙は後続の処理に適したサイズにカットされます。

• 接着: 強力な接着を確保するために、通常は水性またはホットメルト接着剤の接着剤層をコア紙とクラフト紙の表面に塗布します。

3. ハニカム構造の形成:

• 折り畳み:芯紙は折り畳み機を用いてハニカム構造に折り畳まれます。この工程では、構造の均一性と強度を確保するために、正六角形のハニカムを形成するための精密な制御が求められます。

4. 絆:

• ラミネート加工:クラフト紙とハニカム紙の芯をラミネーターで組み合わせ、高温または高圧で接着剤の硬化を促進し、2層の紙が剥離することなくしっかりと接着されるようにします。

5. 切断:

• 切断: 接着されたハニカム紙ロールは、高精度の切断装置によって必要なサイズと形状に切断され、きれいなエッジとバリのない状態が保証されます。

6.品質検査:

•検査:製造されたハニカムペーパーは、自動検査システムによって不完全性、剥離、その他の欠陥がないか検査され、製品の品質が確認されます。

7. 包装および保管:

•梱包: 認定されたハニカム紙ロールは、通常、輸送と保管を容易にするために防湿性と防塵性の材料を使用して梱包されます。

8. 自動制御:

•制御システム:生産ラインには、各リンクの動作を調整し、生産パラメータを監視し、効率的で安定した生産を確保するための自動制御システムが装備されています。

製品開発の方向性:

全自動クラフトハニカム紙ロール製造機の生産ラインの設計と研究は、生産効率の向上とエネルギー消費量の削減に重点を置いています。高度な自動化機能とリサイクル可能なクラフト紙を設計に統合することで、製品性能を継続的に最適化し、製紙技術の進歩を加速します。

製品パラメータ

| 保証 | 1年 |

| ロゴと色 | ロゴと色のカスタマイズを承ります |

| ダイカットスティックの有効幅 | 550mm |

| 有効巻き戻し幅 | 540mm |

| ダイカットロール | Φ240*600(ヘリカル歯) |

| ダイカットボトムローラー | Φ240*600(合金鋼+メインサーボドライブ) |

| まとめ | 300ローラー摩擦巻き取り |

| 自動給餌装置 | 1.5KW油圧システム |

| 自動偏差補正システム | 110 同期電動シリンダ補正 |

| 機械サイズ | L*W*H (4840*2288*2100) |

| スピード | 5~280m/分 |

| 力 | 6KW |

| 電圧 | 380V/50HZ |

| 重さ | 2500KG |

| 自動チューブローディング装置 | (紙管自動装填+インフレータブルシャフト自動装填+自動ポンピング+インフレータブルシャフト自動配置+インフレータブルシャフト自動巻き取り+完成品自動配置) |

当社を選ぶ理由

1. 自社生産工場、競争力のある価格、大規模な倉庫を保有

2. 独立したR&Dセンターが徹底したカスタマイズを提供

3. 特定のディーラーサービスネットワーク

4.ワンストップのパッケージングソリューションと一連の製品ビデオ(操作、アフターセールスなどを含む)を提供します。

5. 3対1のアフターサービス、即時対応

技術サポートとサービス

*インストールガイダンス:インストールビデオ資料とR&Dエンジニアによるオンラインガイダンスを提供します。

*アフターサービス:3対1のアフターサービスドッキング、即時対応

* 工場の利点: 工場からの直接卸売配送、独自の工場卸売価格

* ユニークなカスタマイズ:独自のR&Dエンジニアがおり、カスタマイズされたロゴとブランドカラーを受け入れます

* 1年間の保証:保証期間中、共通スペアパーツは無料で交換いたします。オンラインで解決できない場合は、専任の担当者が現地でサポートいたします。

以下に、知っておきたい質問をいくつか挙げます。

全自動ハニカム製紙機とは何ですか?

ハニカム抄紙機は、クラフト紙をロール状のハニカム紙に加工する専門機械です。ハニカム紙は、貴重品の包装や保護に適しています。ハニカム紙芯材は、その独特な特性からサンドイッチ複合材用途に広く利用されています。YJNPACKのハニカム紙芯材には、対応するデジタル番号が埋め込まれているため、各製品を識別し、原産地まで遡ることができます。これも製品の利点の一つです。

ハニカム製紙機に投資することを選択できるのはなぜですか?

新しいビジネスチャンスを探している場合、またはビジネスチャネルを拡大したい場合は、引き続き以下を参照してください。

ハニカム紙製造機に投資すれば、さまざまな仕様、サイズ、色のハニカム紙包装ロールを大量生産できます。

現在の包装トレンドからすると、輸送時の保護やギフトの装飾など、ハニカム紙包装が主流となり、広く使用されるようになるでしょう。

ハニカム紙包装ロールが製造された後、次のことが可能になります。

1. ビジネスの幅を広げ、輸送保護資材として現地の物流倉庫に提供したり、Amazonやeコマースなどのプラットフォームに提供したりします。

2. 自社生産のため追加の梱包材が不要となり、調達コストを削減できるため、梱包材の在庫不安を解消できます。

3. 1 年間の保証が付いた自給自足型の生産ラインに投資し、3 年間の機械の返品率を計算します。