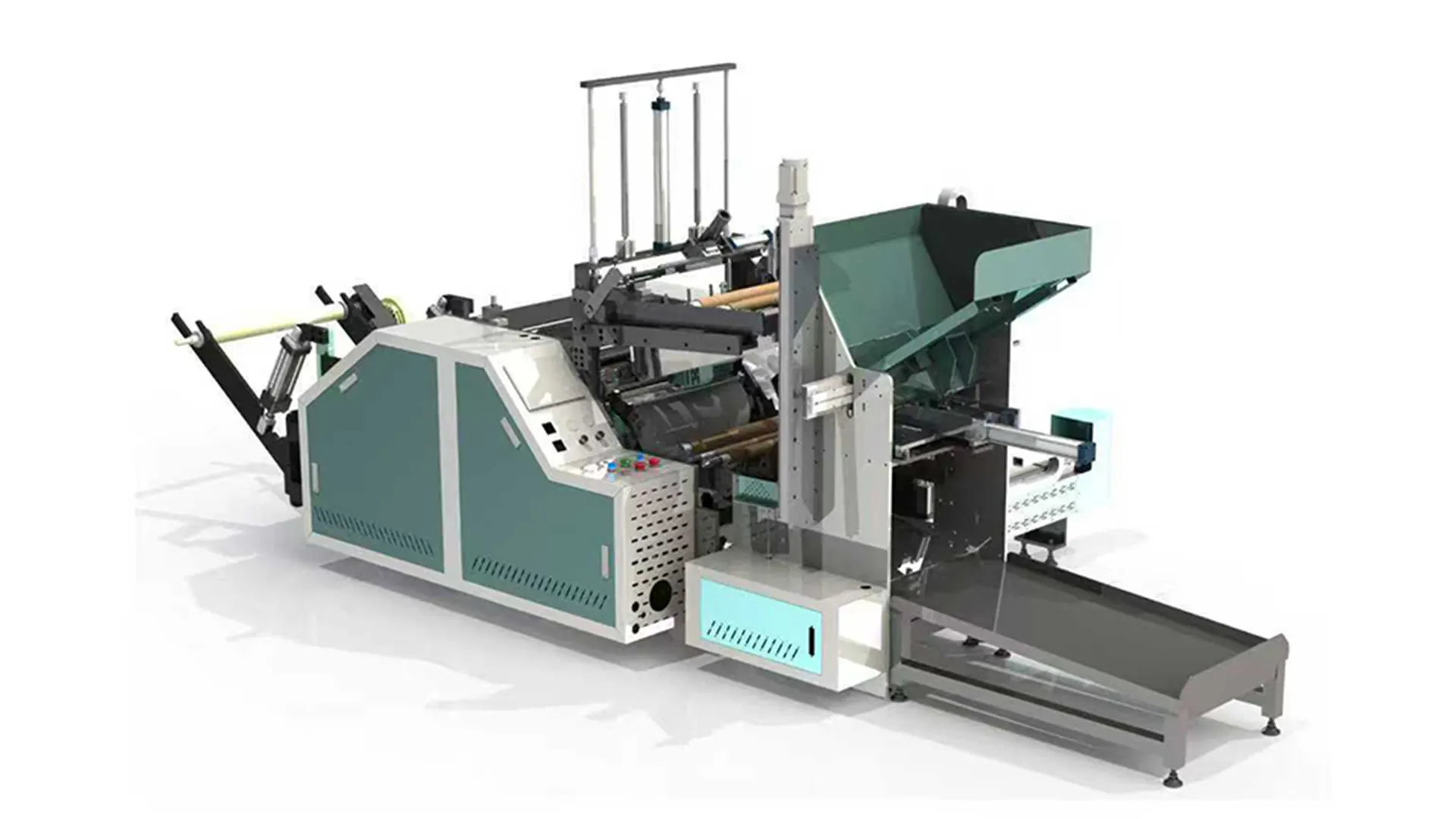

YJNPACK Full Automatic Honeycomb Paper Making Machine

About Full Automatic Honeycomb Paper Making Machine Working Principle

The fully automatic honeycomb paper making machine production line adopts an advanced mechanical design and control system to realize an automated production process, including key links such as automatic feeding, forming, pressing, and cutting. And it has Automatic tube loading device and automatic correction system to achieve efficient and reliable production.

Based on high-speed forming and pressing technology, it also has 110 synchronous electromechanical cylinder corrections. Through a series of cutting and forming and 300-roll friction winding processes, the kraft paper is quickly formed and pressed to form a honeycomb structure and finally produces honeycomb paper of various specifications.

The fully automatic honeycomb paper roll making machine production line is an efficient and automated production system for manufacturing honeycomb paper rolls.

Honeycomb Paper Making Machine:working principle and production process

1. Raw material preparation:

• Kraft paper roll preparation: The production line uses high-quality kraft paper as raw material. The surface paper is usually tougher and is used for the outer layer; the core paper is used for the inner honeycomb structure.

2. Paper processing:

• Cutting: The paper is cut to a size suitable for subsequent processing to ensure accuracy and consistency.

• Gluing: A layer of adhesive, usually water-based or hot melt adhesive, is applied to the surface of the core paper and kraft paper to ensure a strong bond.

3. Honeycomb structure formation:

• Folding: The core paper is folded into a honeycomb structure through a folding machine. This step requires precise control to form a regular hexagonal honeycomb to ensure the uniformity and strength of the structure.

4. Bonding:

• Lamination: The kraft paper and the honeycomb paper core are combined in a laminator, and high temperature or pressure is used to accelerate the curing of the glue to ensure that the two layers of paper are tightly bonded without delamination.

5. Cutting:

•Cutting: The bonded honeycomb paper roll is cut into the required size and shape by high-precision cutting equipment to ensure neat edges and no burrs.

6. Quality inspection:

•Inspection: The produced honeycomb paper is inspected by an automated inspection system to check for incompleteness, delamination, or other defects to ensure product quality.

7. Packaging and storage:

•Packaging: Qualified honeycomb paper roll is packaged, usually using moisture-proof and dust-proof materials for easy transportation and storage.

8. Automated control:

•Control system: The production line is equipped with an automated control system to coordinate the operation of each link, monitor production parameters, and ensure efficient and stable production.

Product development direction:

The design and research direction of the fully automatic kraft honeycomb paper roll making machine production line is dedicated to improving production efficiency and reducing energy consumption. By integrating advanced automation functions and recyclable kraft paper into its design, it continuously optimizes product performance and accelerates progress in the field of papermaking technology.

Product Parameters

| Warranty | 1 year |

| Logo & Color | Accept logo and color customization |

| Effective Width Of Die-cutting Stick) | 550mm |

| Effective Unwind Width | 540mm |

| Die-cutting Roll | Φ240*600(Helical Tooth) |

| Die Cutting Bottom Roller | Φ240*600(alloy steel+main servo drive) |

| Wrap-Up | 300 Roller Friction Winding |

| Automatic Feeding Device | 1.5KW Hydraulic System |

| Automatic Deviation Correction System | 110 Synchronous Electromechanical Cylinder Correction |

| Machine Size | L*W*H (4840*2288*2100) |

| Speed | 5-280m/min |

| Power | 6KW |

| Voltage | 380V/50HZ |

| Weight | 2500KG |

| Automatic Tube Loading Device | (Automatic loading of paper tube + automatic loading of inflatable shaft + automatic pumping + automatic placement of inflatable shaft + automatic winding of inflatable shaft + automatic placement of finished product) |

Why Choose Us

1. Have its own production factory, competitive prices, and large warehousing

2. An independent R&D center can provide in-depth customization

3. Specific dealer service network

4. Provide one-stop packaging solutions and a series of product videos (including operation, after-sales, etc.)

5. Three-to-one after-sales service, immediate response

Technical support and service

*Installation guidance: Provide installation video materials and online guidance from R&D engineers

* After-sales service: 3-to-1 after-sales service docking, immediate response

* Factory advantages: Direct factory wholesale delivery, unique factory wholesale price

* Unique customization: Have our own R&D engineers, accept customized logo and brand color

* 1-year warranty: Free replacement of common spare parts during the warranty period. If the problem cannot be guided online, we will arrange for a dedicated person to provide on-site guidance

Here are a few questions you may want to know:

What Is The Full Automatic Honeycomb Paper Making Machine?

The honeycomb paper making machine specializes in processing kraft paper into rolled honeycomb paper. Honeycomb paper is suitable for packaging some valuable items and protecting them.Honeycomb paper core materials have been widely used in sandwich composite applications due to their unique properties, and YJNPACK's honeycomb paper cores will have corresponding digital numbers embedded inside them so that each product can be identified and traced back to the source. This is also one of the product advantages.

Why can you choose to invest in a honeycomb paper making machine?

If you are looking for a new business opportunity or want to expand your business channels, you can continue to browse:

Invest in a honeycomb paper making machine, you can mass-produce honeycomb paper packaging rolls of different specifications, sizes, and colors.

From the current packaging trend, honeycomb paper packaging will be mainstream and widely used, whether it is for transportation protection or gift decoration.

After the honeycomb paper packaging rolls are produced, you can:

1. Broaden your business path and provide it to local logistics warehouses as transportation protection materials, or provide it to Amazon, e-commerce, and other platforms

2. Eliminate your packaging material inventory anxiety, as self-production does not require additional packaging materials, and reduces procurement costs

3. Invest in a production line for self-sufficiency, with a 1-year warranty, and calculate the return rate of the machine within a three-year period.