How Pallet Wrapping Machines Can Transform Your Commercial And Industrial Packaging

What Are Pallet Wrapping Machines Used For?

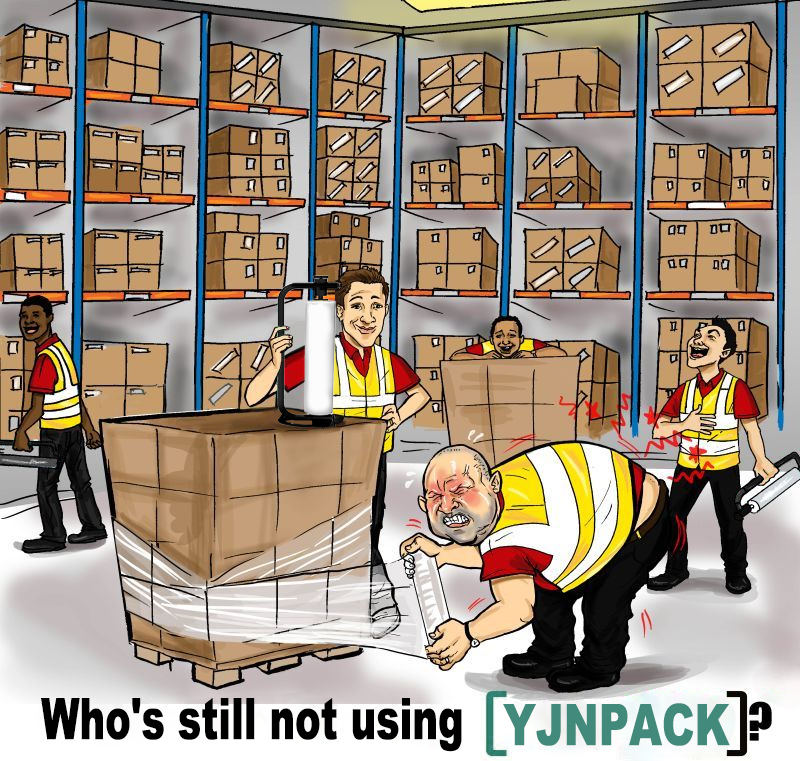

Pallet wrapping machines are used to wrap and reinforce multiple stacked boxes on a pallet to keep them stable, firm, and safe for

transportation and storage, even for heavy items. They stretch the film evenly and wrap it around the goods, perfectly fitting around the goods,

which can improve the safe transportation and stability of the goods in the process, and improve efficiency while wrapping, without the disaster

of stopping and putting the boxes back because a box falls off when moving after the boxes are stacked.

Types Of Pallet Wrapping Machines

1. Automatic self-propelled robot pallet wrapping machine

This machine combines automation and intelligence into one machine operation. The packaging site does not limit it and can automatically wrap

and pack the goods. It has a powerful PLC programmable system, so its load weight is not limited. In addition, it can automatically detect the height

of the goods and wrap them at an average pre-stretching ratio of 200%~250%. The process can be carried out automatically without human intervention.

It is an ideal choice for bulk cargo transportation wrapping, which can further improve packaging efficiency.

2. Semi-automatic pallet wrapping machine

This machine requires manual participation in the bundling process, and can only wrap and pack pallet goods at a fixed position. Therefore,

this machine is more suitable for small and medium-sized packaging and logistics companies with moderate shipments. Compared with the

automatic model, there will be certain differences in its functions and the initial investment cost of the semi-automatic model is lower,

which is a cost-effective choice for small and medium-sized enterprises.

3. Handheld wrapping film dispenser

The whole process of using this machine requires manual intervention, but it uses lightweight carbon fiber material to make the entire packaging

easy to complete, not limited by the height of the goods, and can wrap the goods on the pallet in any direction so that it can obtain safe cargo

transportation at the lowest cost.

4. Electric portable hand-held stretch film dispenser

This product does not require any electricity has a 4000 mAh lithium battery and is suitable for PP and PET strapping materials. It

can easily tighten and weld strapping tapes and can package some heavy items: such as wood manufacturing, stone manufacturing, and

other carton transportation. It is cheap and suitable for some small transportation companies.

Purpose Of Strapping Wrapping

Tightly wrapping the cargo on the pallet with stretch film or strapping can ensure that it will not move during transportation, reduce

the risk of cargo damage ensures its safe delivery and also improves the overall packaging efficiency.

Correct Use Of The Strapping Packaging System

It is very simple to use. You only need to place the cargo steadily on the pallet, and then wrap and strap the cargo according to the operation

of the pallet wrapping machine. The machine will automatically wrap, cut, and wrap.

Notes:

During use, please be sure to operate according to the machine's operating manual and make a regular maintenance plan. Regular cleaning of the

the machine can extend its service life and ensure safe operation.