YJNPACK сосредоточен на производстве упаковочных машин подушкой с 2005 года.

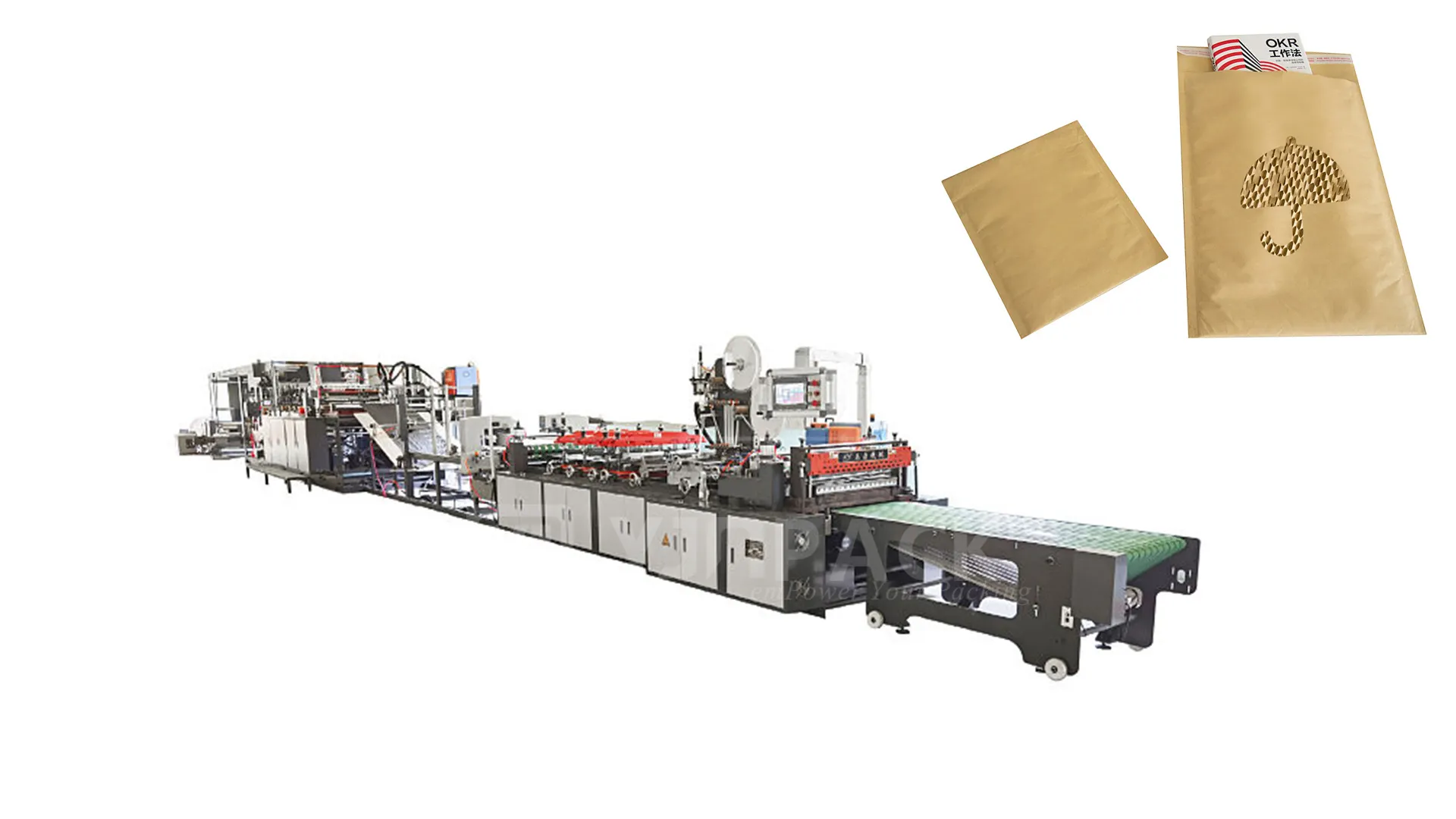

Сотовая машина для изготовления пакетов с сотовой бумажкой

Машина для изготовления пакетов с сотовой бумагой - это специальная упаковочная машина, используемая для производства бумажных пакетов почтовой почты

Самая большая особенность этих мешков конверта заключается в том, что они используются для замены традиционных пластиковых пузырьковых мешков. Внутренняя часть - это прочная и прочная сотовая бумага, легкая и сильная пластичность, в то время как легкий вес, экономия транспортных расходов.

Проектирование машины для создания пакетов с сотовой бумажной почтовой почтой также отвечает потребностям общества в области охраны окружающей среды для устойчивой и разлагаемой упаковки. В основном он ламинирует крафт -бумагу и растянутую сотовую бумагу с водным клеем, и весь процесс является автоматическим и эффективным.

Характеристики машины для изготовления почтовых пакетов из сотовой бумаги

1. Биоразлагаемые: почтовые пакеты Honeycomb Paper – это легкие, прочные, не содержащие пластика пакеты индивидуального размера, подлежащие переработке.

упаковочное решение, которое заменяет традиционную упаковку из пузырчатых пакетов.

2. Обработка сотовой бумаги: Машина для производства почтовых пакетов из сотовой бумаги используется для обработки сотовой бумаги. Сотовая бумага представляет собой конструкцию, в которой несколько слоев бумаги с помощью клея склеиваются между собой, образуя шестиугольную сотовую структуру. Такая конструкция обеспечивает уникальное соотношение прочности и веса, обеспечивая долговечность и амортизацию.

3. Машина для изготовления пакетов: Эта машина может формировать пакеты-конверты из сотовой бумаги заданных размеров и форм. Она выполняет операции фальцовки, склеивания и резки, формируя структуру пакета.

4. Гибкость: машины для изготовления сотовых почтовых пакетов обычно могут обрабатывать пакеты самых разных размеров и конструкций, а пакеты-конверты различных спецификаций также упрощают изготовление разнообразной упаковки.

5. Автоматизация: Эти машины обычно автоматизированы и оснащены передовыми системами управления и механизмами, обеспечивающими точное и эффективное производство пакетов. Они могут включать в себя такие функции, как автоматическая подача, склеивание и укладка готовых пакетов.

Основные моменты производственной линии по производству почтовых пакетов из сотовой бумаги:

1. Сама машина использует передовую интеллектуальную технологию управления: от размотки до резки и формовки все контролируется компьютером.

2. Добавьте электронное отслеживание глаз в настройки параметров, плавное и точное

3. Узел перемотки и размотки оснащен воздушным расширительным валом, что делает загрузку и выгрузку продукции удобной и быстрой.

4. Широкополосный преобразователь частоты управляет всей производственной линией, плавное изменение скорости и отдельные двигатели выпуска и захвата делают производство более эффективным.

5. Автоматизированные машины с управлением от ПЛК и преобразователя частоты. Простая в использовании панель управления.

Параметры продукта

| Ширина размотки | <=1500 мм |

| Скорость изготовления сумки | 30-60 ед/мин |

| Диаметр размотки | <=1200 мм |

| Скорость изготовления сумки | 30-60 ед/мин |

| Скорость машины | 70 /мин |

| Разматывающий вал | 3 дюйма воздуха, раздувающие вал |

| Общая мощность | 25 KW |

| Размеры машины | 26500мм*2200мм*2250мм |

| Подача воздуха | Вспомогательное устройство |

| Параметры | Ширина мешка: <=800 мм Длина сумки: 700 мм Напряжение: 22–380 В, 50 Гц Вес машины: 13,5 т |

Техническая поддержка и обслуживание

*Руководство по установке: предоставление видеоматериалов по установке и онлайн-руководств от инженеров по НИОКР

* Послепродажное обслуживание: послепродажное обслуживание «3 к 1», немедленный ответ

* Преимущества завода: прямые оптовые поставки с завода, уникальная оптовая цена с завода

* Уникальная кастомизация: у нас есть собственные инженеры НИОКР, принимаем индивидуальные логотипы и фирменные цвета

* Гарантия 1 год: бесплатная замена стандартных запасных частей в течение гарантийного срока. Если проблема не может быть решена онлайн, мы организуем выезд специалиста для оказания помощи на месте.