Best Paper Void Fill Machine Protective Packaging PPO-2

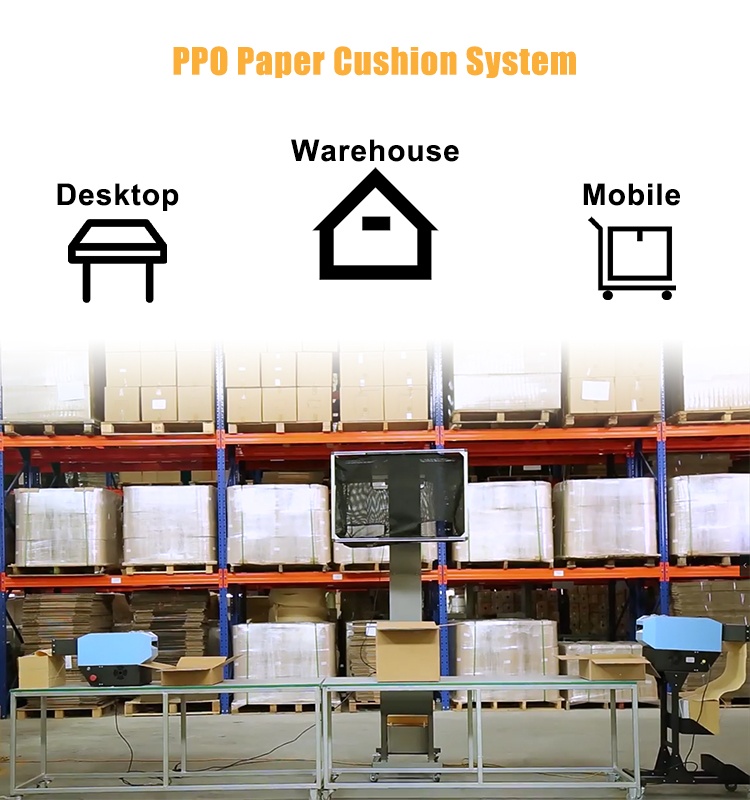

The paper cushion machine can systematically compress and fold double-layer or single-layer kraft paper into a curved shape, so as to achieve systematic protection such as carton gap filling and package protection. The pulley bracket at the bottom can be disassembled or moved as required, and the disassembled paper pad machine can be placed on the desktop for use, and whether it is recycled paper or virgin paper, this machine can be used compatibly, and one machine can achieve multi-purpose functions.

About Paper Cushion Machine

The paper void filling machine is a multi-functional packaging protection machine, the multi-functional

mode operation of the LED screen is suitable for various production and packaging needs. The flexible touch

screen is more convenient to operate. Compatible with recycled paper and virgin paper, roll recycled paper,

high-profile, 100% recyclable kraft paper packaging.

This paper cushion pad machine can also accommodate double-layer kraft paper, and you can choose whether it is

single-layer or double-layer according to your needs. The double-layer kraft paper has a better-buffering effect

and low maintenance, and can better fill and protect. Putting the kraft paper on the shelf separately will have a

better buffering and filling effect on the product.

Paper Cushion Machine Product Details

Removable Packaging

Paper Void Fill Machine is a movable paper cushion packaging machine, which can be combined with the

packaging needs of production lines, express stations, and warehouses.

Easy And Fast Packaging

This paper cushion machine has a user-friendly interface with an LED screen, touch-to-set length, and operation

mode, fast paper feed, and throughput speed also speed up packaging time.

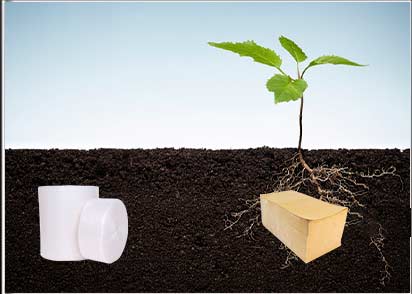

Eco-friendly Kraft Paper

Packed with kraft paper, 100% recyclable and tough. Not only is it eco-friendly, but it has the cushioning and

compression properties of non-transportation plastic materials. The preferred alternative to plastic bubble wrap.

Good Buffering Effect

The gear structure with the design patent can squeeze out a more three-dimensional paper pad, which greatly

improves the buffering effect.

Paper Cushion Machine Details Images

Kraft Paper Packaging VS Traditional Plastic Packaging

1. Kraft Paper Pad Protection

*Recyclable

*Does not take up storage space

*Low price, cost-saving

*Reusable

*A stack of kraft paper with high usability

2. Traditional plastic packaging:

*Take up storage space

*Not recyclable

*Not reusable

*The packaging is messy and difficult to handle

About Us

We are a professional manufacturer of buffer packaging machines and provide one-stop packaging solutions.

*The professional technical team and technical equipment support

*Provide one-stop packaging solutions

*Obtain a professional certification license

*High-quality and high-capacity high-tech products

*One-piece delivery, 1-year warranty, worry-free purchase

*Global sales service, accepting export

FAQ

1. How long does it usually take to ship?

YJNPACK, the general delivery time for samples is 3-7 days, except for special cases.

2. Is it possible to use a double-layer or single-layer kraft paper?

Yes, the paper cushion machine PPO-2 can not only be single-layer or double-layer kraft paper but also recycled paper

and virgin paper can be mixed and placed for double-layer use.

3. Where is the port of departure?

The port of departure is Xiamen Port.

4. Is there an aftermarket package?

We provide a 1-year warranty and provide operation and installation videos.