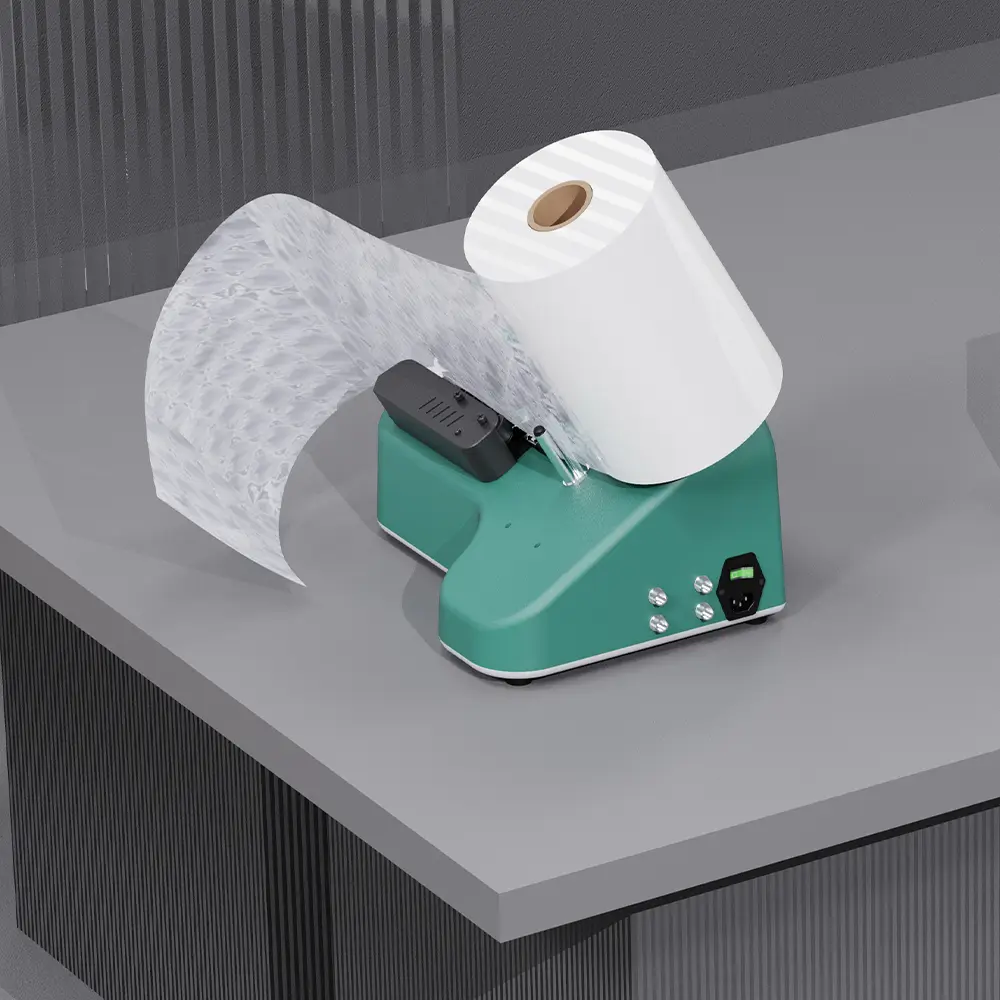

Best Mini Air Cushion Machine For Transport Protection NA-L1

The air cushion machines are excellently suited for quickly and economically filling empty space in one simple step. Equipped with this protective packaging, the goods are fixed in the package preventing migration. For pre-packaged products with minimal risk of breakages.

Large stock, no need to wait, contact us to know more.

Easy Use: Turn on the machine and use it without waiting. Install the roll film, and then choose among 15 specification modes.

After the mode is selected, there is no need to adjust the temperature and air volume, and the operation is simple.

Versatile Film Options: Optional air cushion film of various sizes: 200x100mm, 200x130mm, 200x150mm, 200x200mm, air cushion bubble, air cushion tube.

LCD Panel Display: High resolution, easy to operate, 15 smart specification modes, one-button setting, can meet your needs for filling airbags of different shapes and sizes.

Wear-Resistant Belt: The use of thick and wear-resistant belts does not require frequent replacement. Normally, the belt needs to be replaced only after 200 rolls are used.

The operation is simple and the replacement can be completed in 1 minute.

Compact And Smart: The size is L390 * W290 * H370mm and the weight is only 5.6 kg. It is easy to carry and move, and can meet the packaging needs of warehouses, e-commerce, stores, and express logistics.

No Air Leakage: The air filling rate can reach 95%.The air cushion system has a compact footprint that takes up less dedicated inventory space and only produces air cushion film on demand.

Air Cushion Machine NA-L1 Features

-Use and produce air cushion film on demand

-Fast packaging, average speed 10M/min

-One machine can accommodate various sizes and specifications of air cushion film

-Customized air cushion film size, logo, outer packaging

-Intelligent LED screen can freely adjust the temperature, air, length, etc.

-Small size, easy to carry, packaging size is only 39*29*37CM

-Suitable for packing small and medium fragile and heavy items

-Use degradable air cushion packaging, 0 pollution

-Transparent color appearance, enhance the packaging image

-Compact appearance design can be directly torn by hand without scissors

-Large stock, sample delivery time is only 3-7 days

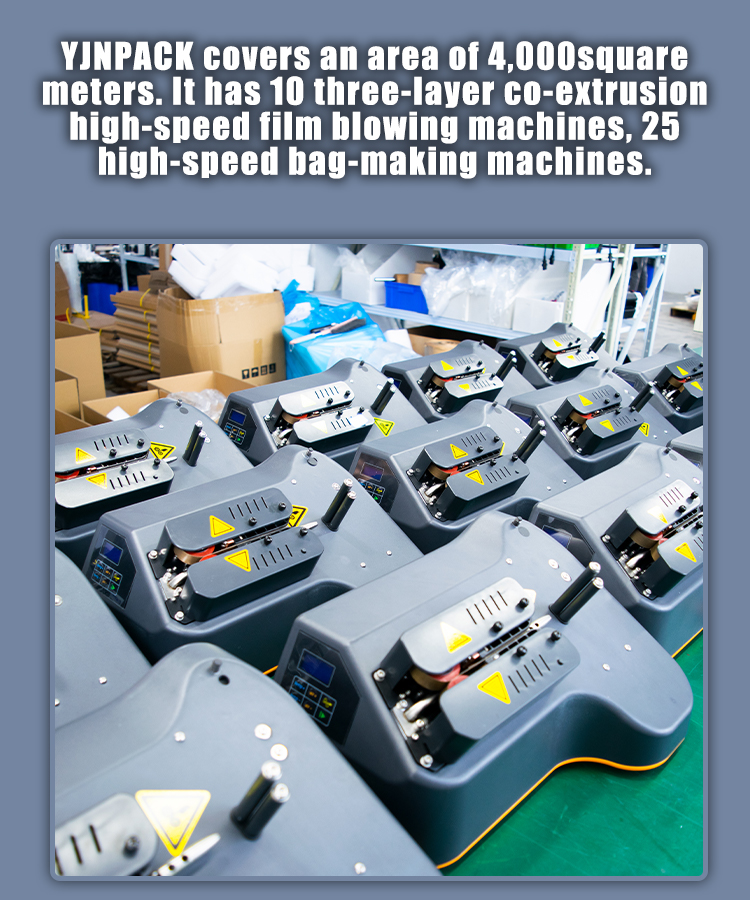

Air Cushion Machine-Factory production process

The air cushion film will go through from production to packaging: raw materials, mixing, blowing, bag making,

and finally the final product.

Air Pillow Packaging Machine NA-L1 Product Details

Easy To Use And Multi-mode Selection

The air cushion machine can be applied to various types of air cushion films, bubble films, or others, which is very

practical and convenient. Made with high-quality material, our bubble air lasts longer than other similar products and

provides better cushion protection. You can choose different sizes according to your product.

LCD Panel Display And Wear-resistant belt

The air cushion machine has a very simple operation interface and every worker can easily get started, it only takes 10 seconds

to heat up successfully after starting. And you can set the air, temperature, etc. according to your needs, most people can

easily get started.

Compact And Smart And No Air Leakage

The product size is 39*29*37cm and the weight is only 5.6 kg. It is easy to carry and move, Air filling rate can reach 95%.

Machine running speed is 10M/min, and air filling speed belongs to the leading industry level.

Air Cushion Packaging VS Traditional Foam Filling

1. Choose an air cushion packaging solution:

*Eco-friendly and biodegradable packaging

*Customized logo, size

*Cost savings and storage space

*Improve packaging image

*Can pack heavy products or other fragile items

2. Traditional bubble wrap:

*Easy to cause warehouse chaos

*Not environmentally friendly and difficult to recycle

*Takes up too much storage space

*Unsightly packaging

The inflation speed is fast and the operation is simple. Compared with traditional plastic and foam packaging, the air

cushion film is lightweight and has low transportation costs. It will be the best choice for you to choose packaging

materials.

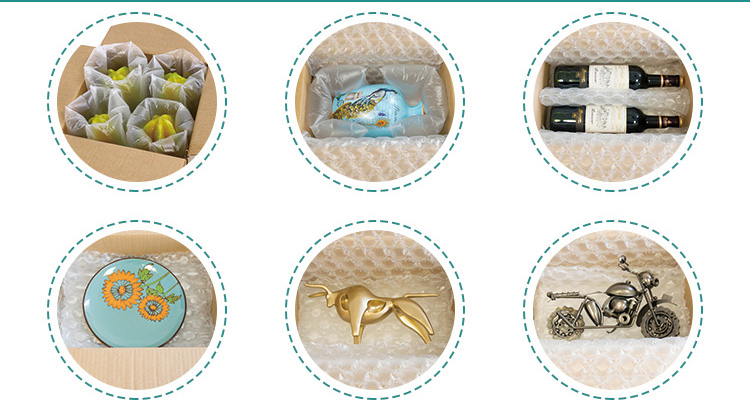

Air cushion Machine Product Case

Air cushion packaging is to inflate rolls of air-cushion film, bubble film, etc. by adjusting the temperature and the

number of meters of the air cushion machine. So as to achieve the function of filling carton voids and protecting

products, it is suitable for protecting valuables, ceramics, heavy items, etc., so that your items can arrive safely.

About YJNPACK

We are a professional manufacturer of buffer packaging machines, providing a variety of packaging machine materials

and products, escorting thousands of express terminals, and obtaining maximum benefits for your market. We will be

your most reliable packaging solutions manufacturer partner.

*Has R&D center, production center, global sales network, and after-sales service

*Committed to the global marketing of various protective packaging equipment and materials

*Obtained multiple professional certificate licenses

*Strict quality inspection department and sales, delivery, brand system

*Excellent service, high-quality products, and competitive prices

*Provide a full range of packaging solutions for your maximum benefit

FAQ

1. What are the main factors that affect the price?

It depends on the size, material, quantity, and customized Logo or not.

2. Do you accept OEMs?

Yes, we accept customized Size/Color/Specification According to your Inquiry. You can send us all of your requirements.

3. What are your warranty terms?

We provide a 1-year warranty for our air cushion machines.

You might want to know about these.

1. What Is The Air Bubble Film Machine NA-L1?

2. How To Use The Air Cushion Machine?

3. What is an Air Cushion Machine?

4. What Is Air Pillow Packaging?

What Is The Air Bubble Film Machine NA-L1

The Air Pillow Packaging Machine NA-L1 is a space-saving, on-demand inflatable air cushion packaging solution

and a perfect alternative to plastic foam filling. Although the air cushion machine is small in size, the packaging

volume is only 39*29*37, which does not take up too much space, and the operation interface is simple and

clear, which it convenient to use. You can easily switch between air cushion film and bubble film according to your

packaging needs.

The air pillow packaging machine can also be called an air cushion machine and an inflatable air pillow machine. The

shell is made of smooth metal material and has a simple and easy-to-operate touch LED screen. One machine can be used

for air cushion films of various sizes and different inflatable materials, allowing you to save more materials.

The air cushion film can also be used on demand without causing material waste. The air cushion film can withstand

objects of about 90kg. Even large, heavy products or fragile items can be transported quickly and safely. The average

speed is 10M/min. After finishing, it can be directly torn by hand to improve packaging efficiency.

How To Use The Air Cushion Machine?

The air cushion machine is a very simple and practical packaging machine. Install the selected type of air cushion film

on the pole of the air cushion machine, then find the opening of the air cushion film to perforate, adjust the air, and

The temperature on the LED screen is set to suitable values, and start the switch to inflate to form an air cushion or air pillow.

What is an Air Cushion Machine?

The air bubble film machine is an integrated general-purpose inflation system, which can produce the air-cushion film,

air bubble film, or air pillows with only one air cushion machine. The intelligent operating system increases productivity.

The air-cushion film can also be customized in size according to needs, effectively filling the gaps in the carton and

protecting the transported products.

What Is Air Pillow Packaging?

An air pillow, also known as an air cushion, is a cushioning packaging material formed by filling the biodegradable air cushion

film with air. Fill them in the voids of the carton to prevent the transported items from being damaged by migration,

collision, and crushing.

| Item | Air Cushion Machine |

| Model | NA-L1 |

| Warranty | 1 Year |

| Logo & Color | Accept logo and color customization |

| Port Of Departure | Xiamen Port |

| Parameters |

Power: 150W |