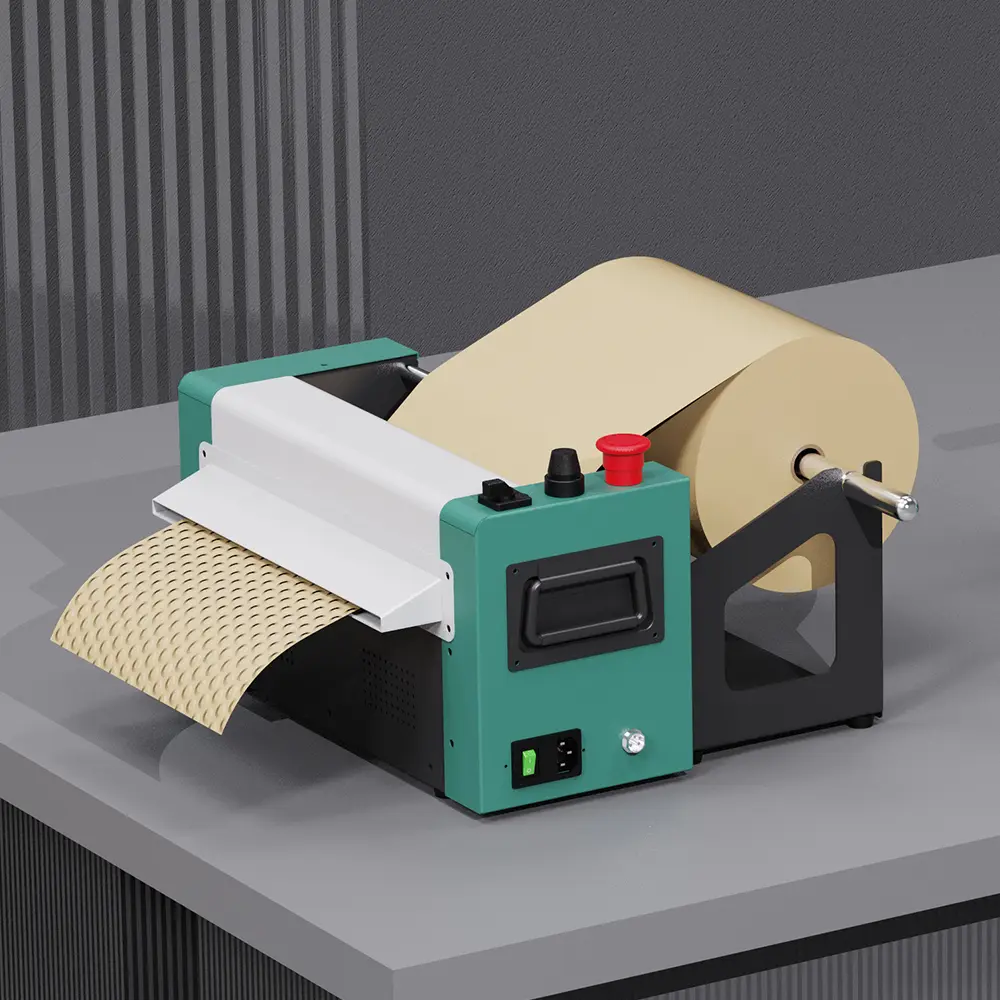

YJNPACK 300mm Paper Bubble Machine PB100

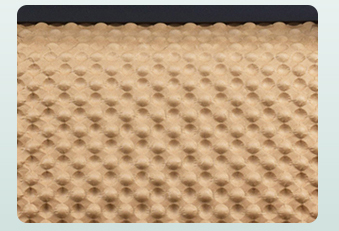

The new paper bubble machine is an innovative packaging solution, mainly used to produce concave-convex packaging cushioning materials from base paper or roll paper, and is a paper-based substitute for traditional bubble filling. Widely used in carton filling, wrapping, padding, and cushioning. due to the large air bubbles on the surface, it can achieve a high degree of product protection and efficient material usage.

Paper bubble wrap is a new type of packaging solution, mainly used to produce kraft paper bubbles with concave-convex surfaces to replace traditional plastic and bubble packaging, and can be used in food, fruit packaging, and daily canned, easy-to-use Broken goods, valuables, large industrial supplies, etc., to achieve multi-functional use across industries.

About Paper Bubble Machine PB100

Also, using a paper bubble machine can make the packaging more beautiful and provide a high-quality unboxing

experience. And paper air bubbles wrap is 100% recyclable, so they won't put pressure on the environment. The weight of

the bubble press is only 18kg. Compared with other large packaging machines, it can reduce transportation costs

and lower investment costs, also is a fast, safe, beautiful, sustainable, and attractive way to pack fragile and valuable items.

Product Parameters

| Item | Paper Bubble Machine PB100 |

| Warranty | 1 Year |

| Logo & Color | Accept logo and color customization |

|

Size

|

450*430*240mm |

| Packing Size | 500*310*360mm |

| Suitable Paper | Organ paper, roll paper |

| Applicable Weight | 80-160g, 300mm, standard weight 80g, 250m/roll |

| Pressure Bubble Size | Diameter 12mm, height 5mm |

| Extended function | External pedals and a slide knife can be added |

| Speed | up to 10m/min |

| Paper Application | 300mm,500mm |

| Parameter |

Weight:18KG |

Paper Bubble Machine PB100 Details

Easy To Operate

Just install the paper roll, and then the start switch will run automatically without other complicated steps.

Eco-friendly Bubble Paper

Paper air Bubble Wrap is a 100% recycled material with great cushioning properties. The paper is pressed into a

concave-convex elastic shape, which is very impact-resistant.

Low Cost But Versatile

The paper bubble machine is small in size, can be moved freely in the office area without taking up space,

and has a wide range of uses. It can be used to pack various fragile and valuable products, durable and low cost.

Make Packaging Simpler

It can be used together with a cutter to make the packaging more flexible and simple, and the paper bubbles can

fully play the role of shock absorption.

Here are a few questions you may want to know:

Why would you choose a paper bubble machine for packaging?

1. The paper bubble machine is a new packaging machine in the packaging market. Its simple operation and cutting with a cutter make it faster to package.

2. Secondly, in terms of use, it is suitable for Fengqin paper and roll paper, including 300mm and 500mm. Even the paper can be customized with patterns and colors. It is multi-functional and can meet a wide range of product packaging.

3. The environmental protection and versatility of paper bubble wrap are worthy of appreciation. why? While it can replace traditional plastic packaging, its dual-purpose paper can meet the needs of different dealers and can be used for packaging, shock absorption, cushioning protection, or gift decoration.

It will be a new market product breakthrough for some medium and large e-commerce logistics, warehouses, and dealers.

4. The paper bubble machine can be equipped with a durable and reliable external cutter, which can achieve clean cutting after packaging.

It is available in 300mm and 500mm widths to meet different packaging needs, providing a flexible, economical, and environmentally friendly solution.

Does The Paper Bubble Machine Work?

When you have a paper bubble machine, you can use the paper bubble wrap to produce raw paper or kraft paper

into a paper-based packaging material with a concave-convex surface, which can be used to wrap various items, such

as valuables at home, wine casings, Protection, and wrapping of metal products or some fragile items and other items.

It has a wide range of uses and the scope of application involves households, industries, or e-commerce logistics industries.

What Is The Explanation Of The Paper Bubble Dispenser?

A paper bubble dispenser that produces concave-convex bubbles, including the function of air inlet and concave-convex

shape formation, so that although the surface is similar to the unevenness of bubbles, it is actually an eco-friendly recyclable

packaging cushioning material.

The rolls are manufactured with deep indentations shaped like air bubbles. 5mm indentation depth provides

plenty of cushioning. These "bubbles" act as shock absorbers, effectively cushioning the shocks that the item

may experience during transportation.

What Is The Paper Bubble Machine?

Paper bubble machines are a unique variation of traditional bubble machines that use paper-based components to generate and

release air bubbles. The overall structure and frame are composed of kraft paper rolls, raw paper, and some metal alloy materials.

The machine uses flat kraft paper to form air bubbles through the fusion of the motor and the fan and forces the air bubbles to pass through the door, which determines the direction of the air bubbles.

This type of paper bubble machine is often seen as an eco-friendly and creative alternative as it uses recycled kraft material and

offers unique and novel visual and packaging effects.

How Does The Paper Bubble Machine Work?

The paper bubble machine puts kraft paper or high-strength kraft paper of a certain weight into the machine. The gears inside the machine are used to pleat and shape the kraft paper to produce bubbles, which are then cut using a cutter. The produced kraft paper bubbles also have the characteristics of strength, toughness, and softness, and are often used to package valuables, precious, fragile goods, industrial products, medical supplies, etc.