Paper Cushion Machine:Eco-friendly Packaging Revolutionary Pioneer

Table of contents:

1. The Shadow Of Excessive Use Of Traditional Plastic Packaging

2. Paper Cushion Machine - Pioneer Of The Green Revolution

3. Market Analysis And Data Display

4. Advantages Of Paper Cushioning Solutions

5. Conclusion

The Shadow Of Excessive Use Of Traditional Plastic Packaging

Excessive use of plastic packaging, whether for the environment or for human life, causes visible and multifaceted damage to the ecosystem,

including ocean, soil, air, and food pollution. From the production of plastic packaging to the inability to be fully recycled, according to data,

380 million tons of carbon dioxide are generated each year, accounting for about 2% of the world's total emissions. This does not include

additional carbon emissions generated during subsequent processing.

The United Nations Environment Program pointed out in its latest report that global plastic pollution is being dumped into the ocean at a rate of

nearly 9 million tons per year, and it is expected that by 2050, the weight of plastic in the ocean will exceed that of fish. And these pollutions will

also directly threaten human health.

Paper Cushion Machine - Pioneer Of The Green Revolution

The paper cushion machine uses a simple and energy-saving production process and 100% renewable kraft paper as raw material to create and

develop packaging materials that are suitable for various industries and have high-quality cushioning and protective performance. The heavy-duty

industrial paper cushion machine NP-EC 760 and the cost-effective paper void fill machine NP-P2 3.0 meet the needs of various industries.

The working principle of the paper void fill machine is to press the original ecological kraft paper through the internal gear structure to form a tough and

durable kraft paper pad. These paper pads are not only recyclable but also completely recyclable in the natural environment. From the data, the use of

recyclable kraft paper pad packaging reduces carbon dioxide emissions by 80%, which is economical and has high-quality protective performance.

Examples: Many well-known companies at home and abroad have also adopted kraft paper cushion packaging materials produced by Paper Cushion Machine,

such as Amazon, IKEA, or Muji, which take environmental protection and social responsibility as their core values. According to data, Amazon has successfully

reduced packaging volume by 20% through this innovation, while improving customer satisfaction; IKEA has reduced the use of plastic by more than 2,000 tons

in one year, demonstrating its firm commitment to environmental protection. The successful practices of these companies have proved the huge potential

of Paper Cushion Machine in the field of environmentally friendly packaging.

Market Analysis And Data Display

Compared with honeycomb paper machines and tape dispensers, paper cushion machines have higher initial investment costs. Of course,

there are also cost-effective models, but in terms of long-term investment, for enterprises, the advantages will be much more than the disadvantages,

which can reduce the cost of packaging materials, reduce logistics losses, and enhance brand image. The comprehensive benefits are obvious.

For example, after using a Paper Cushion Machine, an electronic product manufacturer reduced the damage rate of products during transportation by 30%,

and the customer return rate by 20%, and finally achieved a significant reduction in overall costs.

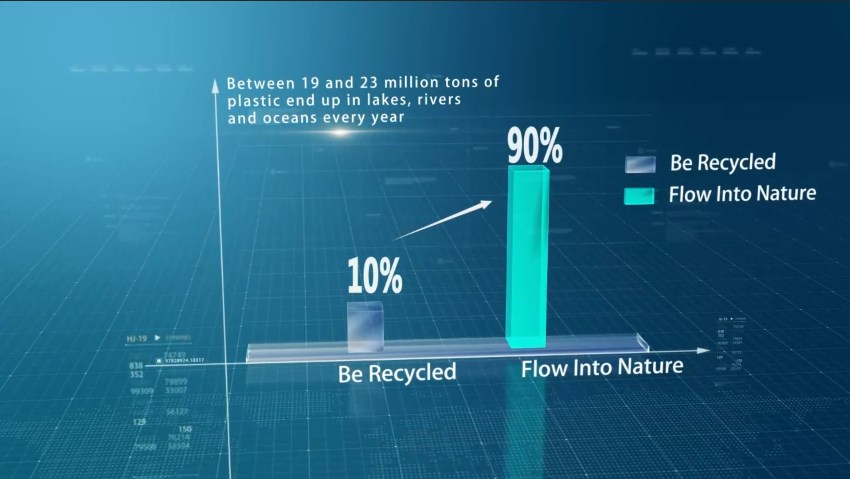

• Market trends: According to the United Nations Environment Programme data in 2023, only 10% of the world's waste can be fully recycled,

and most of it still flows into the ocean. The global green packaging material market is expected to expand at a compound annual growth rate of 8%

and reach a scale of US$115 billion by 2025. This shows that with the improvement of consumers' environmental awareness and the promotion of policies

and regulations, the market demand for green packaging solutions such as Paper Cushion Machine will continue to grow.

Advantages Of Paper Cushioning Solutions

1. Perfect and environmentally friendly packaging material

The tough and durable material of kraft paper provides stronger protection after forming kraft paper pads, and can also be 100%

recycled by the soil, improving the recognition of product packaging and brand impression.

2. Diversified applications

Automatic and intelligent packaging equipment can deeply customize logos and colors to meet the unique packaging needs of

different industries and products.

3. Promote enterprise reform

Paper Cushion Machines has not only changed the face of the packaging industry but also promoted the green transformation of

the upstream and downstream industrial chains and established green packaging standards.

Conclusion

With its unique, stable, and reliable operation and environmental protection concept, Paper Cushion Machine is one of the sustainable choices

for various companies to turn to green packaging. It not only solves the environmental problems caused by traditional packaging but also opens

up a new path for sustainable development for the packaging industry.

Human beings and nature should coexist harmoniously, effectively utilize environmental resources, and work together to create a clean, healthy,

and vibrant home on Earth.