How To Move From Traditional Bubble Packaging To An On-demand Inflation System

How An On-demand Inflation System Can Help

The on-demand inflation system uses an air cushion machine to fill the air cushion film with air and heat seal it. Inflatable packaging

provides protection solutions for wrapping, cushioning, gap filling, and even block and support - the advantages will surprise you:

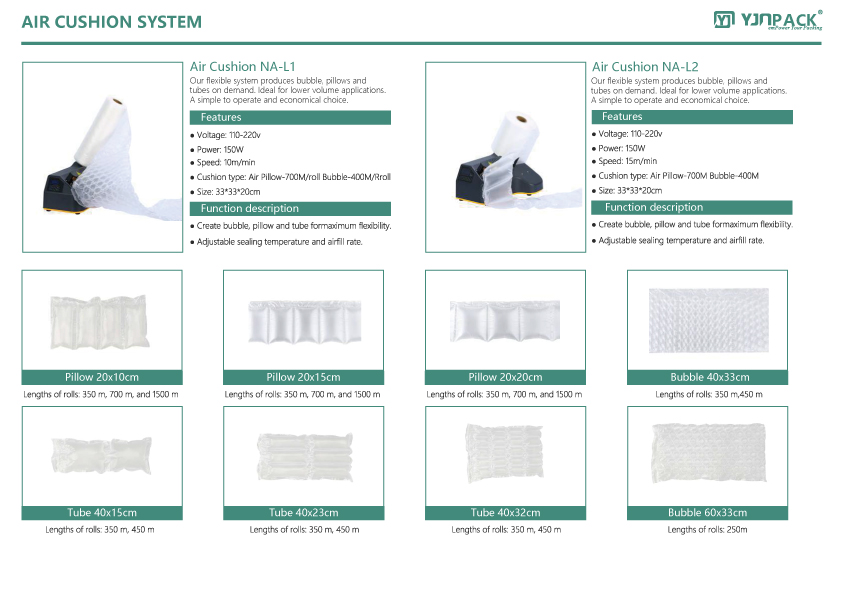

Through the combination of the air cushion overhead delivery system and the air cushion machine protective packaging solution, optional air cushion packaging materials, as well as different specifications of air cushion film, air pillow film, and bubble film are available to increase brand awareness and leave a deep impression.

After the air cushion film is inflated, it can effectively fill the gaps in the box, perfectly integrate with the carton, and ensure that the product is not squeezed and collided in the box, which not only avoids over-packaging but also saves material and labor costs. It also provides a beautiful unboxing experience.

NRTEC provides a complete set of on-demand inflation systems to meet more packaging needs, filling, wrapping, and supporting transportation goods.

The on-demand inflation system can be used with various specifications of air cushion films. It uses compact air cushion films instead of bulky plastic bubbles to accommodate more packaging materials with the smallest storage space. The air cushion films are stacked in rolls, which allows It to take up less storage space can be purchased in bulk, and saves shipping costs.

Improve Efficiency

The on-demand inflation system can be peeled off and placed directly into the box after inflation, simplifying the packaging process and

reducing the movement of packaged products. Once stored, a single air cushion system can feed multiple packaging stations at the same time,

allowing employees to achieve maximum productivity in the minimum amount of time.

Better Handling

The on-demand inflation system is designed for economical operation. This means that the rolls of film used in the system are smaller

and easier to move than pre-inflated bubbles. In addition, operators can inflate the air cushion machine as needed, and then directly tear it apart

for filling and packaging in the box, thereby improving efficiency and making it easier to use.

When Would You Need A Demand Inflation System?

The on-demand inflation system not only simplifies packaging but also minimizes costs and improves return on investment.

Do You Want To Reduce Waste?

The air cushion machine can perfectly fit the shape of the box after inflating it. This maximizes space utilization, thereby reducing overall supply usage, and also reduces some human packaging errors without wasting packaging materials.

Are you looking for rapid growth?

When you have new products coming out soon or need to increase sales targets from your distribution center, then reorganizing with an on-demand inflation system can provide your operational efficiencies while manpower is in short supply.