YJNPack se ha centrado en la fabricación de máquinas de embalaje de cojines desde 2005.

Máquinas de papel para relleno de huecos con logotipo personalizado OEM NP-P10

La máquina llenadora de papel NP-P10 comprime el papel completo y liso, que se puede utilizar para llenar y proteger diversos utensilios, productos frágiles, etc., para evitar que los artículos se muevan. Cuando esta pequeña máquina llenadora de papel alcanza la longitud deseada, debe rasgar la sección manualmente, sin necesidad de tijeras. Si desea ser completamente automático, puede echar un vistazo a nuestra máquina de cojín de papel, completamente automática.

Cur síos ar Tháirgí

YJNPACK NP-P10 paper cushion filling machine has a small footprint, is suitable for 110/220V electrical requirements that meet the standard, and is suitable for small packaging stations.

Our Advantages

Paraiméadair Táirge

Mír | Kraft Paper Pad Cushioning Machine |

| Lógó & Dath | Accept logo and color customization |

| Bharántas | 1-year |

| Luas | 105M/min |

| Cumhacht | 120W |

| Voltas | 110V |

| Meáchan | 25kg |

| Méid | 94*94*164cm |

| Mode | Pedal mode |

Sonraí Íomhánna

1.Strong Security

The inside of the paper filling machine adopts a design of no cutter, and the paper is discharged safely through the switch.

2.Easy To Install

Pass the paper around the bottom bracket and turn on the power. The bottom bracket can be adjusted freely by rotating to compress the paper to achieve a buffer effect.

3. Easy To Maintain

Because of its small size, simple maintenance procedures, and mobile wheel device, it can be moved to your convenient location according to your needs.

Industrial Product Packaging

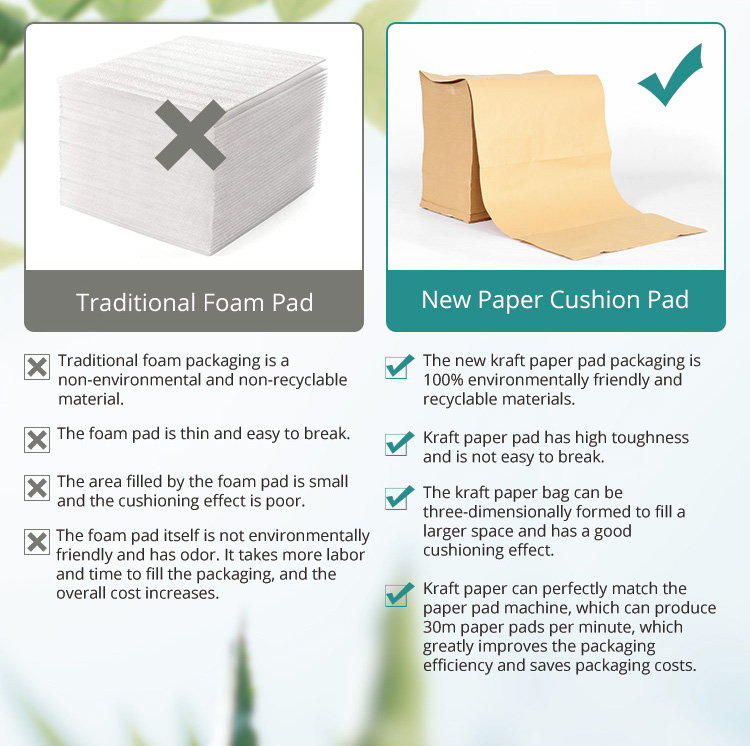

Comparison With Traditional Paper Packaging

About YJNPACK Company

1.Automated Production

2.Five Years OEM/ODM Experience

3.Advanced Production Technology

4.Strict Quality Control System

5.Strong Production Team

FAQ

1.Is the product durable?

Our products have a 1-year warranty, which is not only durable but also long-lasting.

2.What is the voltage of this item?

The voltage of this product is 110/220V.

3.Can you guarantee the product?

Our products have undergone tensile tests, negative pressure testing machines, and gravity pressure limit tests to ensure safety and quality.