Reduce Shipping Damage With Correct Filling Protects The Machine

1. What Is A Paper Cushion Machine?

2. Steps To Operate The Paper Void Fill Machine

3. Advantages of the paper cushion machine

4. Final Words

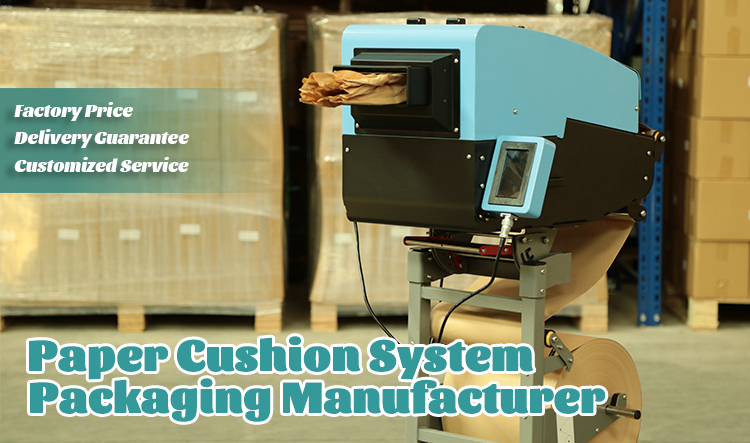

What Is A Paper Cushion Machine?

The working principle of the paper cushion machine is to use the gear part of its internal structure to continuously extrude the flat kraft paper

into a kraft paper pad with a buffering effect under the action of power-on, transmission, extrusion, and other processes, the more obvious the

pattern is. The buffering effect is more pronounced. The paper pad machine is a cost-effective packaging machine that helps multiple packers

create the best packaging solution.

The kraft paper pad can be used as a filler for the empty space inside the carton to ensure the safe transportation of the product. Also, the most

common types of kraft paper are base paper and recyclable paper, plain kraft paper, you can use any of them in the paper cushion machine.

The most exciting feature of this packaging machine is that it is automated and can be operated with a foot pedal. Keep your hand's free while

working on the paper void fill machine.

Steps To Operate The Paper Void Fill Machine

Once you have a paper pad machine, you should know how to operate it. However, if you are new to using it, you must understand how it works

and operates. Here is a detailed guide for the correct use of the paper pad machine;

1. Install the machine

After unpacking the paper pad machine, there are some parts that you need to install yourself. Let's see what these components are and how to use them;

●First, take the caster bracket and install it along with suitable screws and washers.

●The next step should be to adjust the support frame. So make sure to fine-tune it.

●After fixing the frame, attach the support board to the frame. Use precise-sized nuts that fit perfectly in the holes and ensure better adjustment.

●Finally adjust the main unit at the top of the bracket.

2. Start the machine

Finally, your paper void fill machine is now ready to use. So plug in the power cord and turn it on. Place it on the cardboard by shaping the kraft paper into

a triangle. The triangular shape allows the paper to enter the machine easily and efficiently.

In order to introduce paper into the machine, you must press the enter button. It is more convenient for the paper to enter, and the bottom bracket can be

adjusted in height to suit the packaging for various occasions

3. Adjust the Operations

For achieving the desired paper cushions, certain adjustments are made. Generally, there are three operating buttons on the machine, each controlling a

different function.

● Start and stop button.

● Modes adjustment button.

● Length determining button.

The two operations except mode adjustment are pretty simple to use. Whereas, you might get confused while adjusting the modes. With this button, you can

deal with three different modes, represented by different letters.

Here are the modes of paper void fill machine;

➔ Pedal Mode

If you choose to use pedal mode, this means that when you press the pedal, the paper will move inside the machine. On the other hand, releasing the foot pedal

tends to cut through the paper coming out of the machine. Therefore, this mode allows you to decide the length of the paper pad by pressing the pedal.

➔Auto Mode

Automatic mode is also called counter mode. In this mode, the length of the paper is set. Therefore, the machine continuously discharges sheets of a preset length.

➔ Length mode

As the name suggests, this mode requires adjustment of the desired paper pad length. After setting the length, the machine will automatically cut the paper pad to the

exact length.

Advantages Of The Paper Cushion Machine

Paper cushion machines are widely used in the packaging industry with their remarkable features. Some of the main advantages of this machine are discussed below;

●Easy To Use

The best part of the paper pad machine is its ease of use. Thanks to the pulleys on its bottom you can easily move it from one place to another by dragging it. Furthermore,

in addition to being simple to operate, it can be fastened easily and quickly.

●Various Configurations

Another popular feature of this machine is its multi-mode operation. The multi-machine configuration makes the packaging process look cool and smooth. In addition, it

allows you to correctly measure paper gap fill.

●Energy Saving And Environmental Protection

The paper pad machine produces recyclable paper pads, which are both energy-saving and environmentally friendly. So while protecting your cargo, it also protects the

environment from pollution.

●Provide high security

Kraft paper pads are more compressive than regular paper. It has almost a buffer volume of up to 30%. These paper pads proved to be excellent shock absorbers when

traversing rough trails. As a result, the product is safer and less likely to be damaged.

Final Words

Finally, you are there with fine knowledge about the working and operation of the paper cushion machine. No doubt, paper cushions are ideal void fillers and are pretty

versatile in their use. So, what are you waiting for, it’s time to say goodbye to all unsustainable packaging and welcome eco-friendly paper void fills.

You’ll surely love the performance of this packaging material during the transit of your goods.