OEM Inflatable Air Bag Cushion Filling Machine AP400 Transport Protection

The air cushion machine allows you to fill the air cushion film into air pillow packaging, air cushion film, and other air cushion packaging, which can be inflated and used immediately, saving costs, and providing instant gap-filling or cushioning solutions for various packaging applications.

Why Choose To Use Air Cushion Packaging?

These air cushion machines fill air cushion film, bubble film, etc. to form air pillows, air cushion packaging filling

materials, or pillows to protect your goods. It is a substitute for plastic packaging and the most environmentally

friendly choice for packaging gap filling, blocking and support, and cushioning protection.

The use of air cushion packaging can be used on-demand, will not cause material waste, and save warehouse space

and costs. With strong protection, it is your first choice for packing and filling materials for transporting fragile goods,

valuables, and electronic products.

Advantages Of Air Cushion Machine

-One machine to produce various sizes of inflatable protective packaging materials

-Adjustable air volume, temperature, and length

-On-demand packaging materials

-Speed is 15m/min, improves packaging efficiency

-Customized air cushion packaging to enhance your brand image

-Reduce shipping costs and reduce damage claims

-99% air and 1% recycled materials reduce transportation space and weight

Details Of The Air Cushion Machine

The use of an air cushion machine for packaging filling is simple and easy to use, and the belt can be quickly

replaced, which improves packaging efficiency.

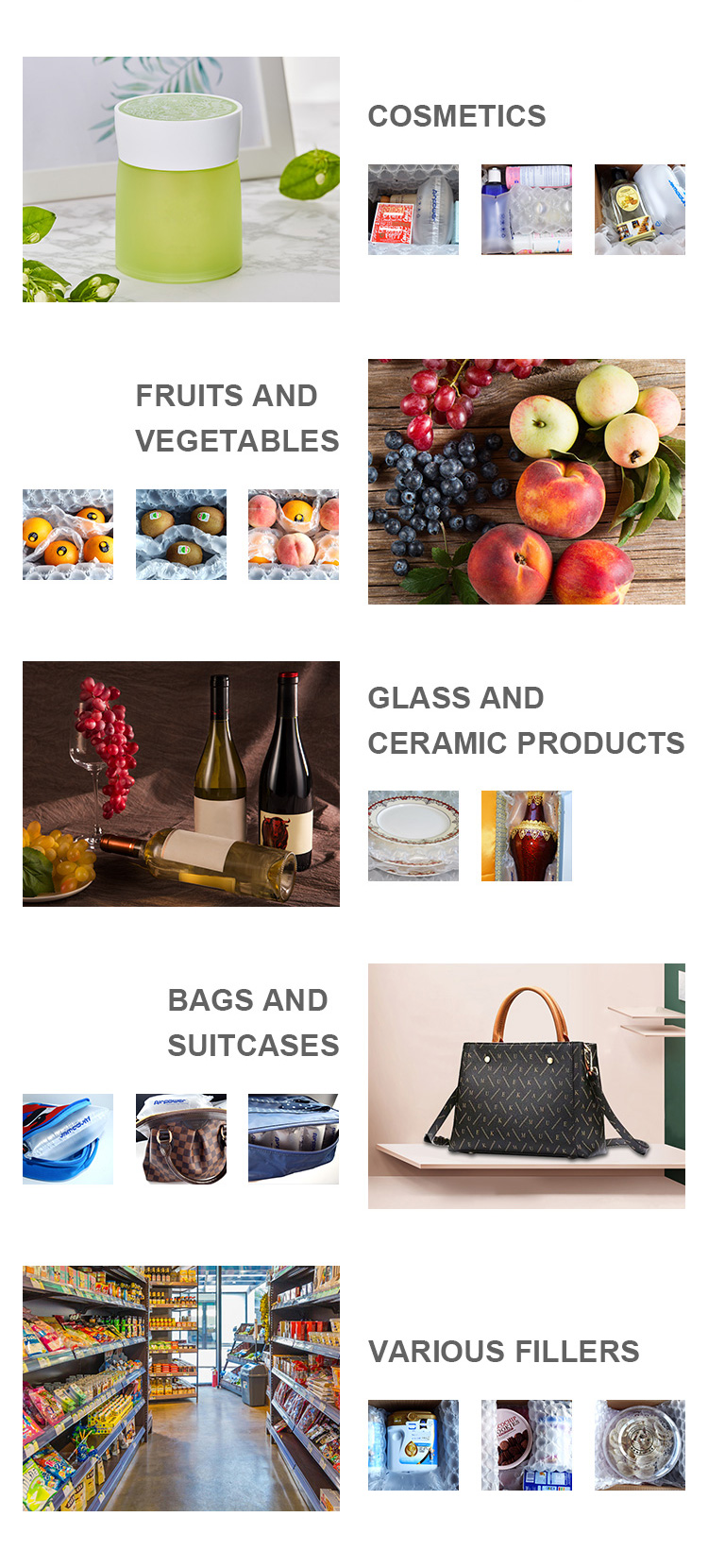

What Can Be Wrapped In Air Cushion Packaging?

Our Company

- Year Established2015

- Business TypeManufacturing Industry

- Country / RegionChina

- Main IndustryOther Machinery & Industry Equipment

- Main Products

- Enterprise Legal PersonChenWenHong

- Total Employees16~100 people

- Annual Output Value300,000

- Export MarketChinese Mainland,European Union,Middle East,Eastern Europe,Latin America,Africa,Oceania,Hong Kong and Macao and Taiwan,Japan,Southeast Asia,America,Others

- Cooperated Customers--

YJNPACK was established in 2015, as a comprehensive enterprise integrating R&D, production, sales, and after-sales. Large-scale plant over 5000 square meters, more than 100 professional skilled workers.

YJNPACK has obtained more than 30 patent certificates through independent research and development of gummed tape machines, air cushion machines, paper cushion machines, and Automatic honeycomb paper machines.

Switching from traditional plastic packaging to packaging with eco-friendly materials means more savings in shipping costs and less pollution. Our packaging machines combine honeycomb paper, air cushion film, kraft tape, honeycomb mailer, Kraft paper roll, and new packaging materials to provide customers with a one-stop packaging solution.

We continue to innovate, launching more than 5 new products every year. Direct factory price, 1 piece delivery, and 1-year warranty, are our promises.