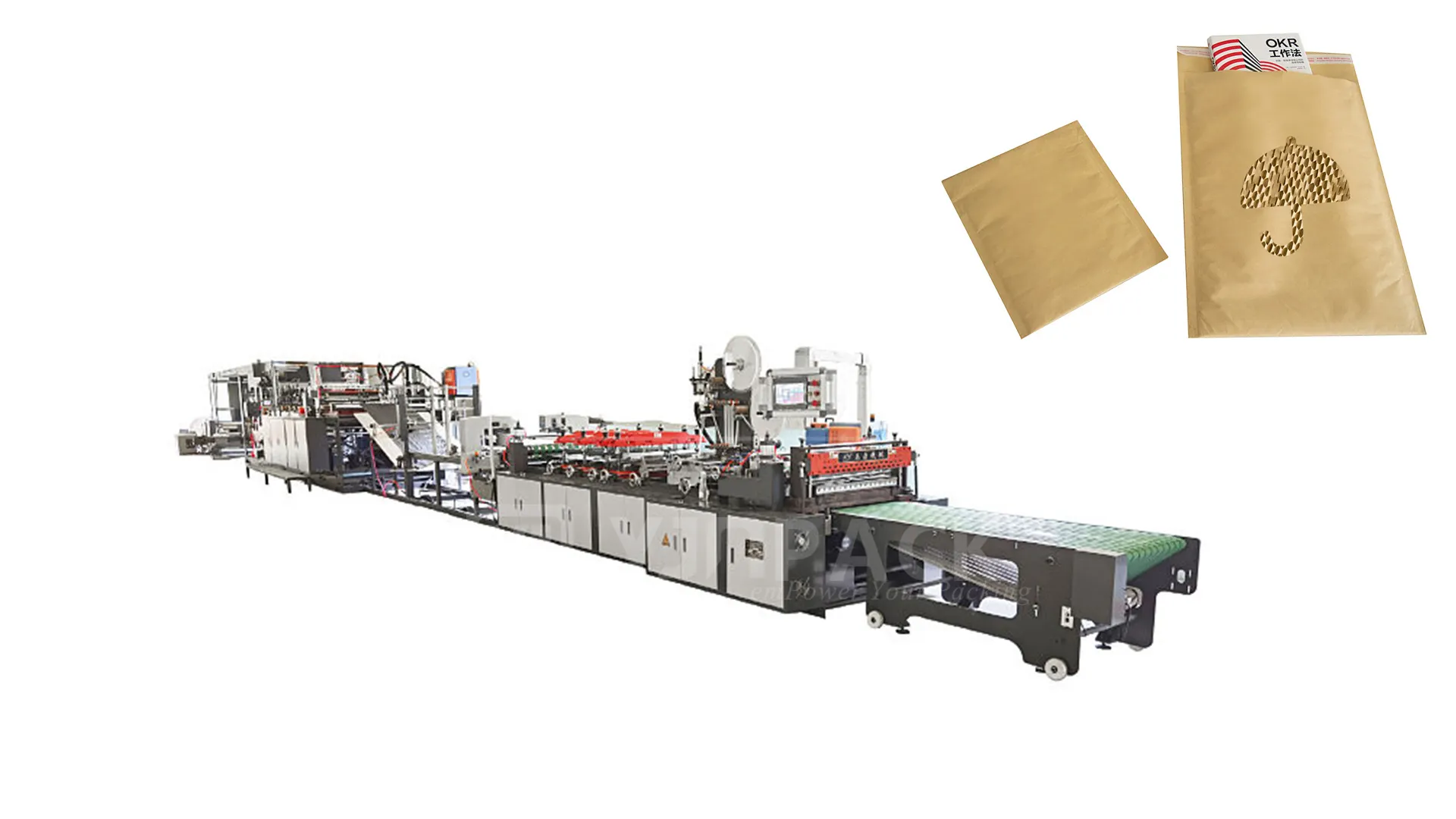

Honeycomb Paper Padded Mailer Envelope Bag Making Machine

A honeycomb paper mailer bag making machine is a special packaging machine used to produce honeycomb paper mailer bags.

The biggest feature of these envelope bags is that they are used to replace traditional plastic bubble bags. The inside is a tough and durable honeycomb paper structure, lightweight and strong ductility, while light weight, saving transportation costs.

The design of the honeycomb paper mailer bag making machine also meets the environmental protection needs of society for sustainable and degradable packaging. It is mainly to laminate the kraft paper and the stretched honeycomb paper with water glue, nd the whole process is automatic and efficient.

Honeycomb Paper Mailer Bag Making Machine Features

1. Biodegradable: Honeycomb Paper Mailer Bags are a lightweight, durable, custom-sized 0-plastic curbside recyclable

packaging solution that replaces traditional bubble bag packaging.

2. Honeycomb paper processing: A honeycomb paper mailer bag making machine is used to process honeycomb paper. Honeycomb paper is to using adhesive bonds to multiple layers of paper together to form a hexagonal honeycomb structure. This construction imparts a unique strength-to-weight ratio for durability and shock absorption.

3.Bag making machine: This machine can form honeycomb paper into envelope bags of specific sizes and shapes. It performs folding, gluing, and cutting operations to form the structure of the bag.

4. Flexibility: Honeycomb mailer bag making machines can usually handle a variety of bag sizes and designs, and envelope bags of multiple specifications also facilitate the realization of various packaging.

5. Automation: These machines are usually automated, incorporating advanced control systems and mechanisms to ensure precise and efficient bag production. They may include features such as automatic feeding, gluing, and stacking of finished bags.

Honeycomb Paper Mailer Bag Production Line Production Key Points:

1.The machine itself adopts advanced intelligent control technology, from unwinding to cutting and forming, everything is controlled by computer

2. Add electronic eye tracking to parameter settings, smooth and accurate

3. The rewinding and unwinding part is equipped with an air expansion shaft, which makes loading and unloading products convenient and fast.

4. Wide frequency range inverter controls the entire production line, stepless speed change, and separate release and pick-up motors make production more efficient.

5. Automatic machines controlled by PLC and frequency converter. Simple to operate control panel.

Product Parameters

| Unwinding Width | <=1500 mm |

| Speed Of Making Bag | 30-60 units /min |

| Unwinding Diameter | <=1200 mm |

| Speed of Making Bag | 30-60 units /min |

| Machine Speed | 70 /min |

| Unwinding Shaft | 3 Inches of Air Swelling the Shaft |

| Total Power | 25 KW |

| Machine Dimension | 26500mm*2200mm*2250mm |

| Air Supply | Auxiliary Device |

| Parameters |

Bag Width:<=800 mm Bag Length:700 mm Voltage:22V-380V,50HZ Machine Weight:13.5 T |

Technical support and service

*Installation guidance: Provide installation video materials and online guidance from R&D engineers

* After-sales service: 3-to-1 after-sales service docking, immediate response

* Factory advantages: Direct factory wholesale delivery, unique factory wholesale price

* Unique customization: Have our own R&D engineers, accept customized logo and brand color

* 1-year warranty: Free replacement of common spare parts during the warranty period. If the problem cannot be guided online, we will arrange for a dedicated person to provide on-site guidance