Safety High Table Carton Packing Band Automatic Strapping Machine

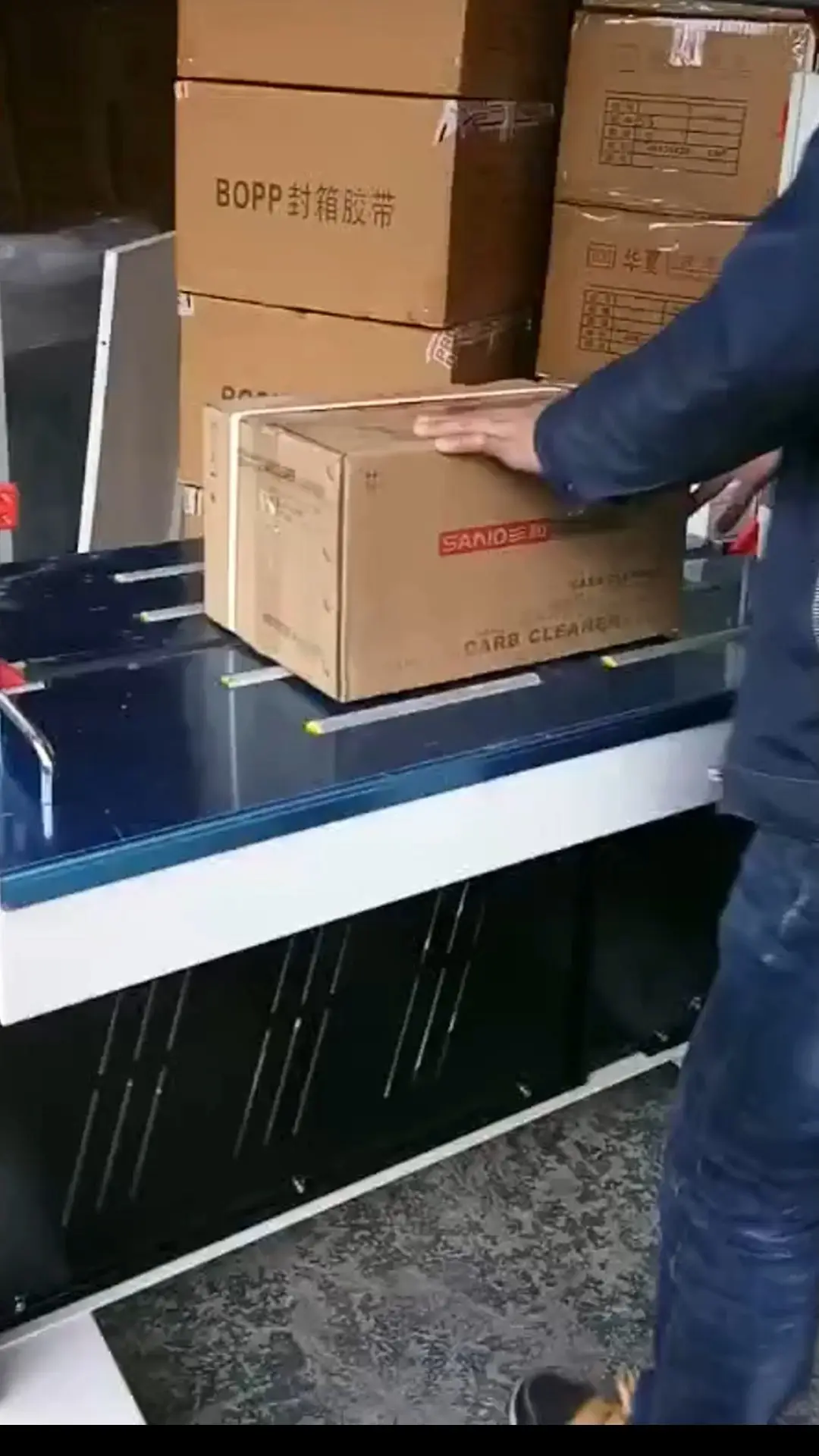

The packing band automatic strapping machine is an intelligent device designed for outer carton sealing. It can quickly tighten and reinforce the carton by automatically outputting the packaging straps, ensuring that the goods are stable and not loose during transportation and storage.

It is suitable for industries that require large-scale packaging, such as e-commerce, logistics, manufacturing, and food processing, and it is especially suitable for users who have high requirements for transportation safety and efficiency.

Whether it is a light carton or a heavy package, the device can adapt to a variety of specifications, realize "one-click strapping", greatly reduce manual operation costs, and improve the level of packaging standardization.

It is suitable for industries that require large-scale packaging, such as e-commerce, logistics, manufacturing, and food processing, and it is especially suitable for users who have high requirements for transportation safety and efficiency.

Whether it is a light carton or a heavy package, the device can adapt to a variety of specifications, realize "one-click strapping", greatly reduce manual operation costs, and improve the level of packaging standardization.

5.0

Model:

MH-X201

MOQ:

1

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Packing Band Automatic strapping machine: core features

1. Fully automatic operation

Without manual intervention, the equipment automatically senses the size of the carton and outputs the straps to complete the entire process of strapping, tightening, and cutting with an efficiency of 300-500 boxes/hour.

2. Intelligent adjustment of tightness

The built-in pressure sensor dynamically adjusts the tightness of the strap according to the material and weight of the box to avoid damaging the packaging due to excessive tightness or falling off due to excessive looseness.

3. Wide compatibility

Supports various material straps such as PP and PET, adjustable width 9-15 (±1), standard frame size: W800*H600 (customized)

4. Energy-saving and durable design

Low-power motor + modular structure, only 1.5 degrees of power consumption for 8 hours of continuous work, and the life of core components exceeds 100,000 times.

5. Safety protection

The packing band automatic strapping machine has an emergency stop button, anti-pinch design, and fault self-checking system to ensure safe operation.

![automatic strapping machine]()

Packing Band Automatic strapping machine:Function and Advantage Analysis

Function 1: Fast Switching Mode

*Supports single-machine manual operation and assembly line linkage mode, seamlessly connects to the packaging assembly line, and adapts to the diverse production rhythm of the factory.

→ Advantage: Reduce downtime and debugging time and improve the overall production line efficiency by more than 20%.

Function 2: Intelligent Counting and Alarm

*Real-time statistics of the number of bundles, and trigger an alarm when the strapping margin is insufficient or the equipment is abnormal.

→ Advantage: Avoid shutdowns due to lack of materials or failures and ensure production continuity.

Function 3: Environmental Protection and Consumption Reduction

*Precisely control the length of the strap with an error of ≤2mm, reduce material waste, and save 15% of the strapping cost compared to manual operation.

![automatic strapping machine]()

What benefits can you bring by investing in an automatic strapping machine?

1. High labor cost

Traditional bundling requires 1-2 people to work continuously, while this equipment can replace 3 workers, saving more than 100,000 yuan in labor costs per year (calculated based on a monthly salary of 5,000 yuan).

2. High transportation loss

Manual bundling is not tight enough, which can easily lead to damage to the box or scattered goods. Using this equipment can reduce the transportation loss rate to less than 0.5%.

3. Efficiency bottleneck

During e-commerce promotions or peak order periods, the equipment can operate 24 hours a day, with a processing capacity of 5 times that of manual labor, avoiding delayed delivery.

Carton Automatic Strapping Machine: Actual benefits for buyers and manufacturers

1. For purchasing companies (such as logistics, e-commerce)

* Cost optimization: The cost of bundling a single box is reduced by 40%, and the return on investment period is less than 6 months.

* Brand value-added: Standardized bundling improves the professional appearance of the package and reduces customer complaints.

2. For manufacturers (such as food and daily chemical factories)

* Capacity upgrade: Seamlessly integrate production lines, increase the average daily processing volume to 15,000 boxes, and easily handle large orders.

* Environmental compliance: Reduce the use of plastic strapping in line with the global trend of plastic reduction and enhance the company's ESG rating.

![automatic strapping machine]()

1. Fully automatic operation

Without manual intervention, the equipment automatically senses the size of the carton and outputs the straps to complete the entire process of strapping, tightening, and cutting with an efficiency of 300-500 boxes/hour.

2. Intelligent adjustment of tightness

The built-in pressure sensor dynamically adjusts the tightness of the strap according to the material and weight of the box to avoid damaging the packaging due to excessive tightness or falling off due to excessive looseness.

3. Wide compatibility

Supports various material straps such as PP and PET, adjustable width 9-15 (±1), standard frame size: W800*H600 (customized)

4. Energy-saving and durable design

Low-power motor + modular structure, only 1.5 degrees of power consumption for 8 hours of continuous work, and the life of core components exceeds 100,000 times.

5. Safety protection

The packing band automatic strapping machine has an emergency stop button, anti-pinch design, and fault self-checking system to ensure safe operation.

Packing Band Automatic strapping machine:Function and Advantage Analysis

Function 1: Fast Switching Mode

*Supports single-machine manual operation and assembly line linkage mode, seamlessly connects to the packaging assembly line, and adapts to the diverse production rhythm of the factory.

→ Advantage: Reduce downtime and debugging time and improve the overall production line efficiency by more than 20%.

Function 2: Intelligent Counting and Alarm

*Real-time statistics of the number of bundles, and trigger an alarm when the strapping margin is insufficient or the equipment is abnormal.

→ Advantage: Avoid shutdowns due to lack of materials or failures and ensure production continuity.

Function 3: Environmental Protection and Consumption Reduction

*Precisely control the length of the strap with an error of ≤2mm, reduce material waste, and save 15% of the strapping cost compared to manual operation.

What benefits can you bring by investing in an automatic strapping machine?

1. High labor cost

Traditional bundling requires 1-2 people to work continuously, while this equipment can replace 3 workers, saving more than 100,000 yuan in labor costs per year (calculated based on a monthly salary of 5,000 yuan).

2. High transportation loss

Manual bundling is not tight enough, which can easily lead to damage to the box or scattered goods. Using this equipment can reduce the transportation loss rate to less than 0.5%.

3. Efficiency bottleneck

During e-commerce promotions or peak order periods, the equipment can operate 24 hours a day, with a processing capacity of 5 times that of manual labor, avoiding delayed delivery.

Carton Automatic Strapping Machine: Actual benefits for buyers and manufacturers

1. For purchasing companies (such as logistics, e-commerce)

* Cost optimization: The cost of bundling a single box is reduced by 40%, and the return on investment period is less than 6 months.

* Brand value-added: Standardized bundling improves the professional appearance of the package and reduces customer complaints.

2. For manufacturers (such as food and daily chemical factories)

* Capacity upgrade: Seamlessly integrate production lines, increase the average daily processing volume to 15,000 boxes, and easily handle large orders.

* Environmental compliance: Reduce the use of plastic strapping in line with the global trend of plastic reduction and enhance the company's ESG rating.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data