OEM Air Cushion Machine AP400 2.0 Air Void Filling System

The new upgraded air cushion machine AP400 uses a new type of shell material in an original way, and the shell with matte texture makes its appearance more advanced. In use, the new air cushion machine AP400 has not changed much. The air cushion machine is an integrated general inflatable system, which can inflate the air cushion film or bubble film one by one as needed to form an air cushion or bubble film. Can withstand various specifications of air cushion film for inflation, improve packaging efficiency on the premise of the intelligent operating system, replace the labor cost of 3 people, simple and easy-to-use LED operation screen, no training or operation teaching, is the best at the end of the production line packaging solutions.

Air Pillow Machine Main Modules:

1. Film Holder

2. Emergency Button

3. Seal The Work Area

4. The extra durable belt inside

2.0 Air Cushion Machine AP400 Features And Upgrade Points

1. No need to warm up

2. The price is lower and more affordable

3. Appearance material upgrade

The biggest difference between the new air cushion machine AP400 2.0 and the old one is that it has added a new

material-heating wire structure, so the most notable feature is that it does not need heating, it can be used with

electricity and there is no need for preheating waiting time, directly connecting the end of the packaging line.

The overall speed has been increased by 30%. Secondly, compared with the original air cushion machine, the new

air pillow packaging machine AP400 has a lower price and is more in line with the current situation of rising raw

material prices, reducing the original cost by 15% in terms of cost.

In addition, the air cushion machine AP400 can be used with an external smart device, which can be a collection frame

(the air cushion film will stop inflating when the air cushion film is full), a foot pedal, a blowing frame system, etc. Under

the premise of maintaining the original speed of 12m/min, It can guarantee one-day shipments and improve packaging

efficiency.

Air Cushion Machine Customization

The Air Pillow Packaging Machine is an on-demand inflatable and efficient solution for filling voids, ensuring that

packages are not damaged in transit. You can customize the unique logo, color, and outer packaging on the

air cushion film and air cushion machine to create an exclusive logo for your personal corporate brand.

Air Cushion Machine Factory Real Shot

The air pillow packaging machine AP400 inflation system can be applied to various production lines or assembly lines,

providing sustainable and efficient packaging solutions, while reducing your packaging costs, labor costs,

and transportation costs.

Air Cushion Machine CE and PSE Certificate

Air cushion machine AP400 is independently developed and marketed by our R&D department, and all have

obtained CE and PSE certificates issued by the state.

Air Cushion Machine Details Images

Efficient Packaging

The maximum speed of the air cushion machine is 12m/min. For some companies with large shipments or large

transportation needs, choosing an air cushion machine is the most perfect solution for your packaging.

Simple Operation Screen

The air pillow machine has a simple operation screen, that adjusts the air, meters, and temperature values to inflate the air

cushion film, and it can run automatically without other operations.

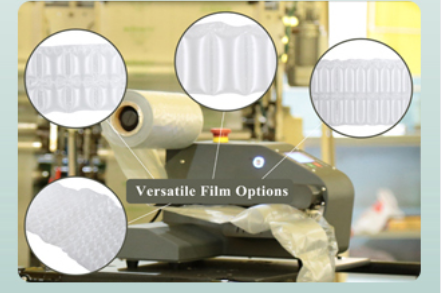

Various film Specifications Are Available

The air pillow machine can accommodate various specifications of air cushion film, which can be air-cushion film, bubble film,

or others, to meet various packaging needs.

External Function

The movable Basket System, foot pedal, Winder System, and Overhead Hopper Film Delivery System can be

connected externally. Make your packaging more flexible.

Air Cushion Machine Production Process

We have our own factories and production and assembly lines. All raw materials are independently developed

and screened to ensure that every part of each product is the best.

About YJNPACK

YJNPACK, make your packaging simpler and make your packaging more environmentally friendly. We are a professional

manufacturer of protective packaging, a comprehensive enterprise integrating R&D, production, sales, and after-sales.

All products we sell are patented and developed and manufactured by ourselves.

Our products are sold all over the country to get the maximum benefit for our customers. We protect at least

millions of packages every day.

YJNPACK, make your packaging simpler and make your packaging more eco-friendly.

We provide you with a one-stop service, allowing you to shop with peace of mind.

*OEM&ODM service

*Self-owned factory guarantees the delivery time

*The whole machine is guaranteed for two years

*During the warranty period, free replacement parts

*Troubleshooting problems, professional and technical personnel answer one-on-one

*Provide solutions and troubleshooting videos

*Provide professional service instructions

*24 Hours Online Reply